Economic in-vessel soil sterilization systems

Stronga in-vessel substrate sterilization systems offer a high duty cycle for highly reliable continuous operation. With an extremely low electrical energy requirement and low labour requirement, FlowSteama Vessa offers the most economic soil sterilisation system available in the market for commercial, large-scale operations. Learn more about the modern-design Vessa Series:

High output, continuous sterilization ✔; ISO modular design ✔; Scalable & expandable ✔; Semi-transportable, relocatable between sites ✔; Easily set-up by the stockpile to reduce handling complexity ✔; Simple & easy to use ✔; Highly controllable with evidenced sterilisation ✔; Fully insulated vessel ✔; Flexible across a range of contaminated substrates (each Vessa is optimised for different substrates) ✔

FlowSteama Vessa

Material temperature sensors located in key locations on both steam decks provide vital evidence that material temperature has been achieved and that material has been maintained at target temperature for the required residency time. Standard Vessa control equipment includes logging, reporting and evidencing soil or substrate pasteurisation, enabling clients to demonstrate to local certification bodies that the heat treatment process has been completed to specified parameters. This is particularly important when onward selling composts, soils and substrates, and is pertinent when the material is crossing borders to prevent international spread of disease.

FlowSteama Vessa is equipped with modern, smart, self-protecting control systems. The visual, operator-friendly touchscreen interface allows instant access to key parameters, at-a-glance, while optional remote access enables operation of the Vessa to be viewed anywhere in the world via Ethernet or mobile. Sensors provide operators with real-time key data to enable optimised efficiency of output and material sterilization.

High output, highly reliable steaming

Stronga in-vessel steam heat treatment systems offer a high duty cycle, enabling high capacity output in continuous operation. Simple, powerful hydraulic operation; no belts, chains or sprockets ensures long life, low maintenance utility. FlowSteama Vessa offers the most economic growing media heat treatment system available in the market when it is coupled with a reliable, well-proven, free-flowing steam generator.

See below a video case study from a material recycling facility we supported on their journey in transforming contaminated soil into an added value, saleable product.

FlowSteama Vessa

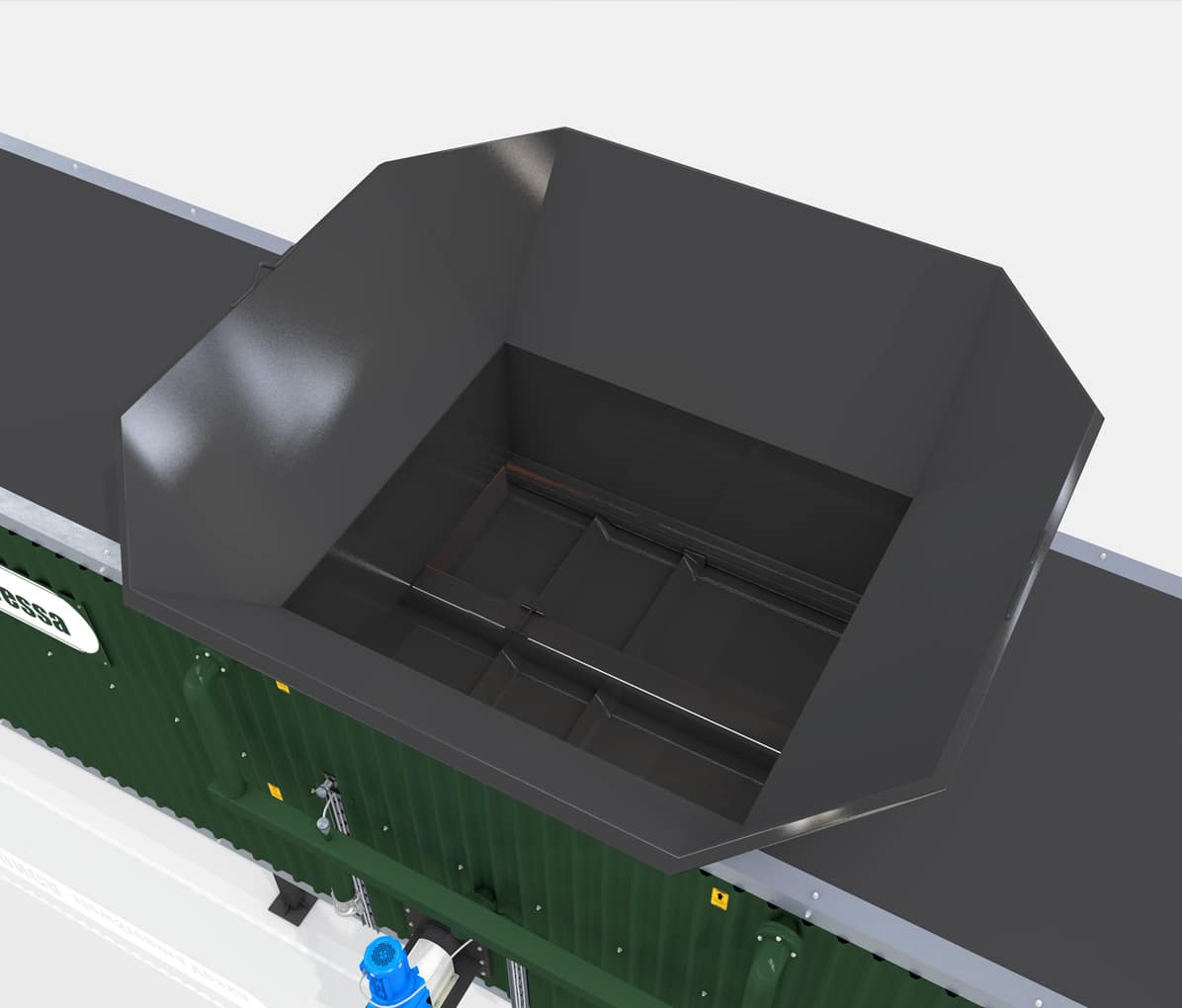

(1) Unsterilised raw organic matter (soil, substrate, compost or other) is loaded by bucket or conveyor into the suitably-scaled, top deck in-feed hopper.

(2) Hot steam from the low pressure, super-heated steam boiler free-flows into the insulated, twin-tier vessel; penetrating substrate on both decks of the PulseWave™ moving floor. The material mixing motion stretches and tumbles the material in the steam chamber and assists in breaking small clods. The material temperature rise is rapid, even and efficient with super-heated steam deeply penetrating the pores of the soil or substrate.

In-feed hopper loading

Loading by bucket or conveyor

(3) Smart controls determine the duration of steam exposure and throughput to suit the substrate and comply with local quality protocols. FlowSteama Vessa controls offer an audit trail, enabling you to confidently evidence that you have held the organic material at temperature for a stated residency time for compliance with local regulations.

(4) Pasteurized soil improver or substrate self-empties from the bottom cross-feed auger onto a rising conveyor for automatic stockpiling or containerisation. Separating clean and contaminated sides is imperative in preventing cross-contamination.

Treatment of soil by heat

There are many crucially-important variables which affect the rate of heat diffusion through the substrate, soil, compost or agricultural manure. Factors to be closely analysed by our experts include soil structure, bulk density, organic matter percentage, moisture content and more. Speak to Stronga for further information relating to heat treating your organic material.

Learn more about the Vessa continuous heat treatment process in the 3D animation below.

Invasive species, sterilised

The well-proven, twin-tier FlowSteama is adaptable across a wide range of soils and substrates, mixes and blends. We offer a choice of models so that the capacity, throughput and scale of Vessa and SteamBoila can be optimised for your operation. Multiple factors are considered in the design of the FlowSteama, including; substrate-type, substrate bulk density, substrate moisture content and more. See below some of the possibilities with FlowSteama in-vessel pasteurization:

Woody biomass residues sterilisation ✔; Green waste sterilisation ✔; Food waste sterilisation ✔; Top soil sterilisation ✔; Compost sterilisation ✔; Mushroom compost sterilisation ✔; Bark mulch sterilisation ✔; Cocoa mulch sterilisation ✔; Coir sterilisation ✔; Organic manure sterilisation ✔; Recycled substrate sterilisation ✔; And more ✔

Standard Specifications

Optional Equipment

Stainless steel package available for corrosive organic matter.

Remote viewing access via Ethernet to desktop or mobile.

| Model | FlowSteama Vessa Series |

|---|

* Other models available on request. Many variable factors exist relating to the client’s material and local operating conditions; speak to Stronga to discuss the details of your heat treatment project.

All weights and measurements are subject to specification and regional laws. As we are continually improving our products, technical details, masses and measurements are given as reference values only.