Steaming Soil to Control Weeds, Diseases & Pests

Soil steam heat treatment is a highly effective method of controlling weeds, soil-borne diseases and insect pests. The main benefit of steam sterilisation is the fast turnaround time where soil can be replanted after a few days, while there is also no risk of chemical fumes damaging nearby crops or harming humans.

Stronga’s FlowSteama and SteamaBoila equipment can be used to heat treat soil up to the temperatures required to kill or inactivate weed seeds, nematodes, fungi, bacteria, and viruses by destroying cell structure and proteins. Steam heat treatment can also be used to disinfect compost, potting soil, bark mulch and more.

The purpose of this guide is to provide useful advice for organisations considering the use of continuous flow, in-vessel soil steaming equipment, and to discuss the key benefits of in-vessel steaming compared to other methods.

Steaming Soil

The following information is based upon research carried out by the highly regarded phytopathologists, Kenneth F. Barker and Carl M. Olsen. Barker and Olsen wrote in their article, ‘Soil Steaming: A Review of Fundamentals’, that steam heat treatment is the best method of treating soil because:

• Steaming is the quickest method of treating soil and the output can be planted as soon as it cools;

• Steaming soil destroys all pathogens, weeds, bacteria etc. whereas some chemicals do not;

• No toxic after effects result from steaming treatment of inert-type soils;

• Steaming can be used without causing undue harm to nearby plants or humans;

• Even including the pro-rata cost of the SteamBoila, the cost of steaming soil is far lower than through chemical treatment.

Diffusion through Soil Pores

When applying steam to soil in the FlowSteama, diffusion occurs through the continuous pores of the soil to the cold area where it condenses, releasing a large quantity of heat at low intensity (a maximum of 100°C).

Steam moves at an advancing front (100°C on one side and unheated on the other) which varies from 1 inch in width and efficient high flow rates or proximity to the input, to several inches wide with low flow rates or greater distance from the input. In this “heating zone”, steam mingles with the pore air, producing an even richer mixture as the temperature rises and the air is pushed out.

Balancing Steam Flow Rate & Soil Quantity

Barker and Olsen suggest that steam moves about twice as fast upward through soil as it does downward or sideways, supporting the “bottom-up” steaming method of the FlowSteama heat treatment system.

A given soil has a maximum condensing rate for steam and once this is exceeded, "blow outs" occur. Once a "blow out" of steam from the soil occurs, steam is bled from the rest of the treatment area and heating is greatly reduced. Greatest efficiency is obtained just below this point, through balancing the steam flow rate and the quantity of soil treated. Through partnering with Stronga for your soil steaming project, you can be sure you are working with a supplier who has experience in designing well-balanced steam sterilisation systems designed to optimise the output of your heat treated soil or substrate.

The Rise & Fall of Chemical Sterilisation

Pesticides and fumigants such as methyl-bromide were introduced to the market in the 1950's when they replaced soil steam heat treatment in managing soil pests. Whilst the effectiveness of chemical pesticides in heat treating soil is undeniable, the damage to the environment is of far greater concern.

Nowadays and since the phasing out of methyl-bromide after the Montreal Protocol in 1987, soil steam heat treatment is regaining popularity in disinfecting soil to manage soil-borne diseases, weeds and other pests. Stronga lead the market of in-vessel soil steaming, offering continuous steaming solutions which have been proven to reliably disinfect soil, topsoil, compost, bark mulch and more.

The video below shows the FlowSteama Rova model steaming soil during a recent trial day.

Conditions for Optimal Soil Steaming

In principle, soil and substrates can be steam heat treated in any greenhouse but there are a few conditions which are important to consider and observe before steaming the soil material:

• The soil must not be too wet. The drier it is, the better. Take this into account during the last watering session before the product is transferred to the FlowSteama.

• Whilst the FlowSteama will actively mix and tumble the product during the heat treatment process, soil must be well and deeply dug beforehand so that the steam can easily penetrate the substrate.

• The soil pH must be 6.5 or higher.

Once the above conditions have been correctly observed, the product can be transferred using a “dirty-side” loading bucket into the FlowSteama top deck hopper. It is vital that the operator handles the contaminated and heat treated materials with different machinery to avoid cross contamination.

What Temperature Do I Need to Achieve?

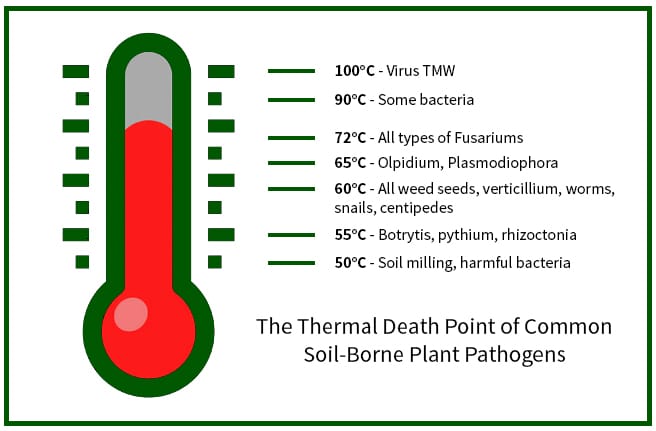

Soil steam heat treatment is the transfer of energy from burning fuel through water steam to heat up soil or substrate to pasteurisation temperatures. The heat input needed to kill pathogens and pests successfully depends on temperature and time. In moist soil, a temperature of 65ºC for 10 minutes is sufficient to kill most pathogens and pests. However, Fusarium Oxysporum and Verticillium Dahliae are more difficult to kill by heat than species of Pythium and Phytophthora.

A higher temperature (90–100ºC) is needed to treat fungi protected in woody stem bases or roots, such as Fusarium Oxysporum within stems, or fungi present as long-term survival structures like Sclerotia of Sclerotinia Sclerotiorum. The benefit of the FlowSteama is its ability to record in real time the temperature profile of the material at 6 points of the in-vessel steamer: (1) input material; (2) and (3) mid-flow material; (4) and (5) both drop points; (6) output material. Temperature profiles of the product are plotted in real-time on the HMI touchscreen; this data can be exported in CSV format to evidence the heat treatment process.

Another benefit of the continuous FlowSteama system is that the moving floor agitates, tumbles and mixes soil and substrate, improving the friability of the material during the soil steaming process. What’s more, the residency time of the material inside the vessel can be adjusted by altering the number of “strokes per hour”. This gives the operator full control of the soil steaming process.

Aftercare Advice

After steaming the soil, good aftercare is of great importance. It is generally advisable to leave the soil to rest for up to a week so that the structure does not deteriorate. When you do start working with the soil again, ensure that your clothing and handling machinery is also disinfected to avoid re-contamination. Furthermore, after planting the soil, it is also important not to immediately overload it with water. The soil structure will not be able to cope with this yet; start with small water sessions and build up slowly.

Aftercare Advice

It is also advisable to revitalise the soil product after heat treatment using beneficial microorganisms such as soil activators, perlite, lime and composts.

When heat treating soil to the high temperatures required for sterilisation deep into the material, practically all organisms die, including the beneficial ones. Killing soil microorganisms diminishes the soil biological activity which will affect soil health and nutrient availability for subsequent crops. In addition, steam killed microorganisms release significant amount of nutrients that were tied up in the living phase of the soil. Therefore, an increase in nutrient availability may enhance vegetative growth in the first crop after treatment, but may require additional amendments for subsequent crops. Consequently, reintroduction of soil beneficial organisms becomes necessary to reactivate the soil biological processes for a healthy and productive soil.

Discovering Alternative Growing Substrates

Governments across the globe are gradually phasing out the use of peat which has led to certain markets, such as the Irish and UK, to source their peat from abroad. This has simply transferred the problem, bringing additional problems involved with transporting peat together with the associated carbon footprint issues.

The future many greenhouses, nurseries and other horticultural organisations are pursuing involves taking weed-burdened soils stripped from construction sites before blending them together with other components, such as shredded green waste, manures, compost and particularly wood fibre.

All of the potentially weed-burdened elements of these blends are the lighter elements which is good news because the heat treatment process is therefore easier and less energy intensive. After heat treatment, in the aftercare process, soil beneficial organisms can be re-introduced to the blend to optimise the output product.

The Business of Adding Value

Many organisations are in the business of bringing together components to create optimised, highly valuable products. Some of these components potentially offer a gate fee charge to the client because there are market pressures to dispose of contaminated products such as soils stripped from building sites. These contaminated products can be heat treated and blended with other components to create a saleable product.

Using Stronga’s reliable, well-proven steam heat treatment systems, businesses are increasingly seeing opportunities to transform a waste stream into valuable, saleable organic matter, topsoil’s and composts. Wood waste and other wood by-products also face the same issue and require heat treatment to ensure the prevention of disease spread. The image below shows the temperature of the heat treated soil discharged from the FlowSteama output cross auger.

Contact Stronga

If you have any questions or would simply like more information about steaming soil with Stronga, please feel free to contact us today to discuss the sterilisation process in more detail – info@stronga.co.uk.

We look forward to hearing from you.

Share this post