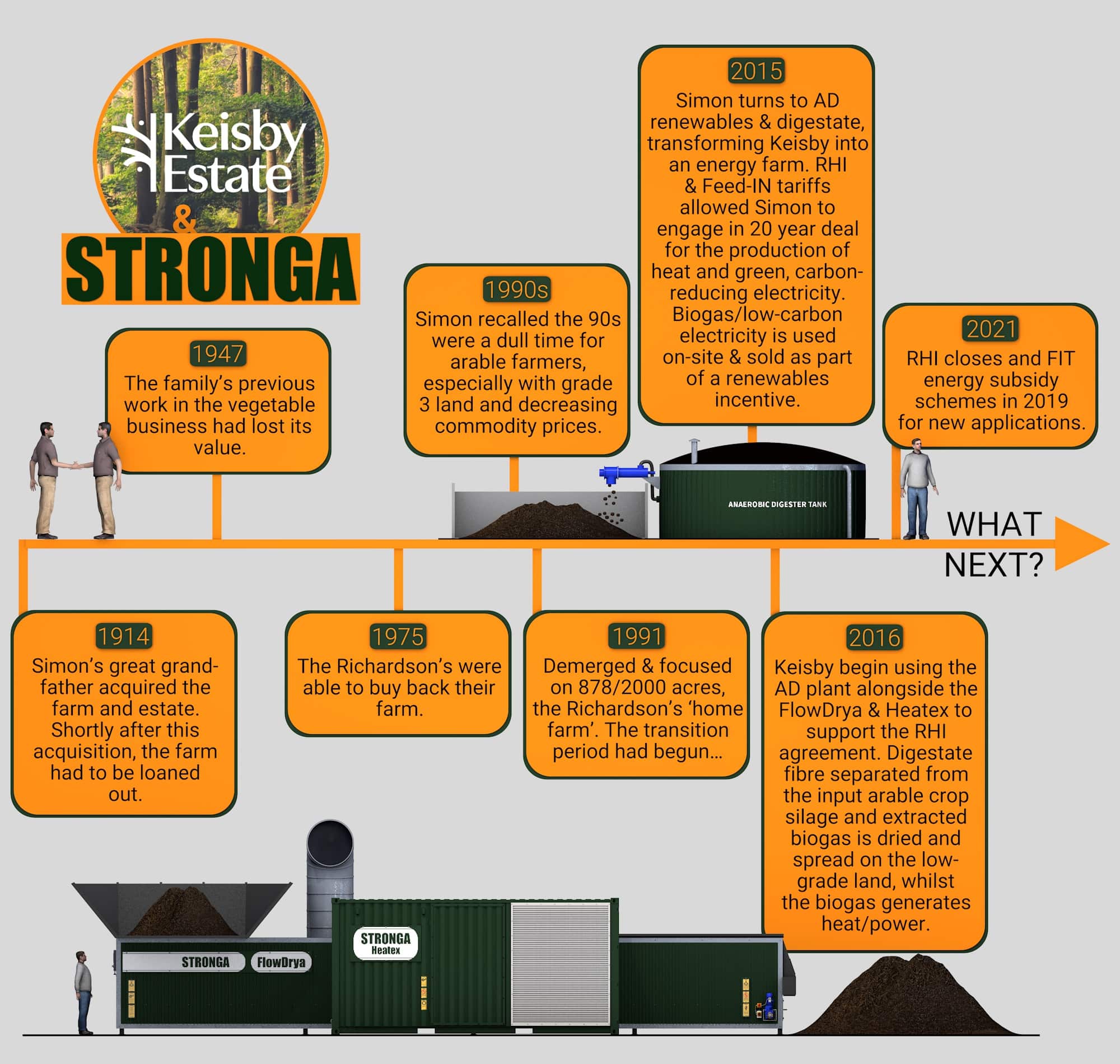

Meet Simon & The Richardson’s;

Mr. Simon Richardson of Keisby Estate contacted Stronga 10 years ago to purchase FlowDrya and Heatex equipment for his 155kW-e AD plant, to utilise and dry the digestate by-product from what was originally a ryegrass silage feedstock, to what is now a spring oats feedstock.

Hard-working and forward-thinking, Simon’s decision to install the AD-plant was significant; taking Keisby forward into the energy-generation business, benefitting the local community through supplying renewable heat and electricity to the grid while positively transforming poor grade-3 arable land by spreading the organic digestate fibre by-product. While RHI and Feed-in tariffs continue to provide Keisby with an additional source of income, Simon and his family are beginning to wonder, what comes next for Keisby Estate?

Long after installing FlowDrya and Heatex equipment on Keisby Estate’s (then) newly-installed Anaerobic Digestion plant; Stronga have recently engaged in further positive conversations with Simon about the future of Keisby. Learn where our recent discussions have led.

A Farming Family Extending Over a Century

AD Renewables X Stronga; Sustainable Synergy

Helping Keisby on their AD journey all those years ago, Stronga’s experienced designers matched the Heatex coil and dual fan specification to fit the client’s CHP heat output. The FlowDrya was also carefully sized to suit the whole crop silage feedstock, to optimise drying of the solid separated digestate fibre fraction.

Once dried, the digestate by-product is better preserved and stored, while it is also transported at a lower cost per ton of material. Over the 10-year period of operation, the FlowDrya and Heatex delivered to Keisby have proven to be highly successful in drying digestate. The graphic below visualises Keisby’s digestate fibre drying process.

To the Moon & Back with Stronga, 5 Times?!

Keisby’s FlowDrya and Heatex have revolutionised resource recovery on the farm, operating reliably over a 10-year period for more than 70,000 hours. For context, if this was a car travelling at 30mph, that would be equivalent of one car travelling over 2 million miles… To the moon and back, 5 times.

With the Feed-in and Renewable Heat Incentive (RHI) contract set to run for a further decade, Simon remains confident that his Stronga equipment will last the duration, and more, continuing to offer excellent reliability in the period.

Uncertainty for the Future Remains

During the initial build of the AD plant at Keisby, Simon faced some considerable challenges, including difficulties surrounding grid connection, looming RHI deadlines, quality issues with the AD plant itself, and the AD plant builder going bankrupt on the day of commissioning. These memories are still vivid.

Fast-forward 10-years, after the hard work of delivering a working farm-scale, AD plant – Simon has turned his digestate drying vision into a success. Nonetheless, uncertainty for the family-farm remains. Important decisions are to be made.

What’s Next for Family Farms like Keisby…?

Those in farming have long faced worsening economic conditions for UK farm produced commodities. Recent political movements have only accelerated considerations of alternative opportunities. Simon has been forced into these alternatives and now remains focused on a future involving habitat creation and biodiversity opportunities.

Biodiversity Net Gain (BNG) is a UK-scheme which offers an opportunity for those with land to create increased financial and natural capital value from habitat diversification. In the very near future, Simon is considering removing 200 acres of his 878-acre farm from crop production, to employ aspects of BNG, with a view to reversing the negative effects of long-term arable production.

The Fundamentals of ‘Biodiversity Net Gain’

BNG represents an opportunity for land owners to restore, protect and improve natural habitats through nature development, habitat creation and climate change reduction.

Recently implemented regulations in the UK are forcing building developers to be BNG conscious, aiming to boost the biodiversity of new developments and prevent habitat destruction. In 2021, the Environment Act inserted the minimum 10% BNG rule introduced by Schedule 7A of the Town and Country Planning Act 1990. Essentially, what this means is that developers must maintain 110% BNG on all projects and ensure they prevent damage to the environment before BNG improvements are accounted for.

The BNG scheme offers opportunities to landowners like Simon Richardson who can sell BNG units to developers unable to fulfil physical BNG gain conditions.

How Does FlowDrya Enable BNG Practises?

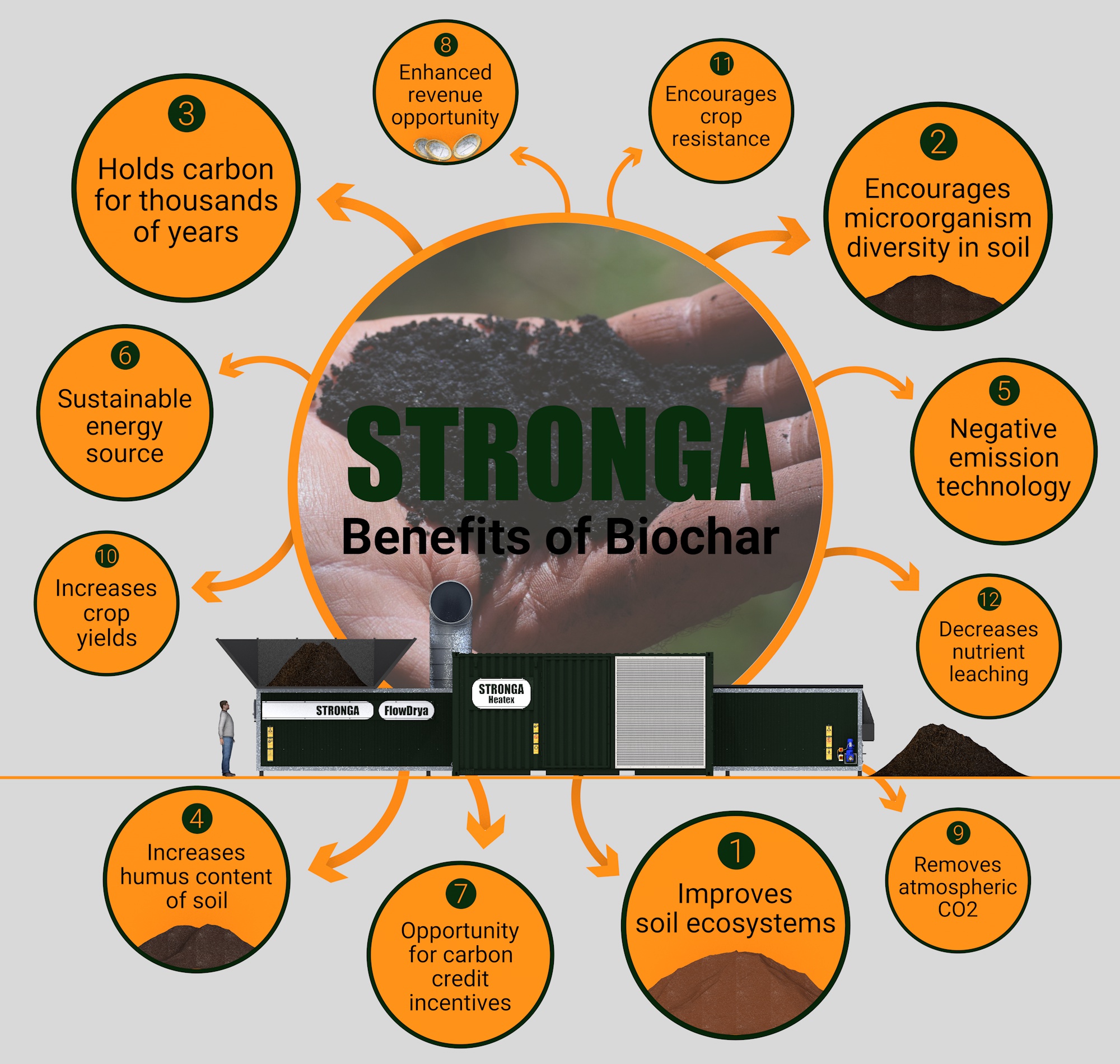

With the potential to combine available digestate fibre output with a supply of waste woodland brash, Simon has the opportunity to create biochar on the farm, using his existing FlowDrya as a key component. After drying the digestate (and wood brash), the biomass can be input into a pyrolysis reactor to produce quality biochar. This biochar project aligns with the main aim of BNG - to restore and enhance nature.

Biochar encourages nature rehabilitation ✓

Biochar helps enhance the poor grade-3 arable farmland at Keisby ✓

Biochar diversifies the soil biome with its beneficial consequences above and below land ✓

Biochar sequesters carbon, locking it into soil for thousands of years while removing atmospheric CO₂ ✓

Biochar would help Keisby contribute to BNG requirements and, through enhancing land prosperity, restore local engagement with nature ✓

Drying biomass down to 15-20% moisture is essential for efficient pyrolysis yield. Stronga recently published an article on our website explaining the benefits of moisture removal for biochar production.

Summarising the Benefits:

1. Stabilises biomass, reducing storage risks and transport costs.

2. Significantly reduces the amount of smoke, pollutants and ash emitted during pyrolysis.

3. Increases the calorific value/heating value.

4. Reduces the amount of reactor faults and other moisture related mechanical malfunctions.

5. Reduces the thermal stresses occurring due to moisture and temperature changes of input material during pyrolysis.

6. Reduces the number of VOCs released into the atmosphere.

7. Increases the homogenous combustion during pyrolysis. High combustion quality due to the decrease in unburnt compounds reduces incomplete combustion.

8. Increased energy efficiency during pyrolysis = better combustion quality and higher quality biochar production.

Applying Biochar to the Land

Despite being originally installed almost 10 years ago, Keisby’s existing FlowDrya continues to provide excellent long-term commercial value. It has given Simon the opportunity to dry digestate, produce biochar and also contribute to carbon-reducing practises that support nature recovery. Keisby’s investment in the dryer made many years ago continues to pay for itself, multiple times over.

Working together with Keisby, our team advised Simon of the benefits of biochar which include; application to the land area set aside for BNG, the cropping farmland, or even selling the resource at good prices to the market, encouraging land enhancement elsewhere in the UK. The decision to employ an existing dryer for biochar production was a no-brainer.

Biochar’s Growing Role in Sustainable Farming

Biochar derived from digestate is nutrient-dense and therefore beneficial for plant growth, especially when mixed with woodland brash. This directly contributes to soil and land improvements, as well as;

- Contributing to Simon’s vision for a natural paradise at Keisby, increasing genuine biodiversity on the farm

- Reducing greenhouse gas emissions (biochar locks up carbon for added soil enhancement)

- Carbon sequestration, directly increasing field carbon store

- Positively contributing to climate change mitigation

- Directly amending poor soils

Biochar improves biodiversity opportunities while mitigating climate change. The graphic below indicates the multifaceted nature of the wonder resource that is, biochar.

10 YEARS ON

After sale, Stronga regularly check in with customers to discuss additional opportunities for each customer’s individual situation. In times where confusion in the farming industry is overwhelming, particularly in the UK, Stronga offer a stable, enduring presence and a strong sense of community for farmers.

Keisby Estate is just one example where our relationship with the customer, and our equipment, has withstood the tough test of time, especially impressive considering the dryer is working with such a corrosive material like digestate fibre.

Adding Lasting Value for Customers & the Environment

Stronga take pride in our long-term engagement with customers, allowing our team to play an active role in optimising the use of equipment and, in this case, optimising resource use. We love finding situations where we see our products are capable of adding real, lasting value for customers and the environment.

With decades of experience in drying digestate, Stronga offers the best advise around; enquire today to begin your journey. Like Simon, you too can bring your vision to life – info@stronga.co.uk

Share this post