Pioneering Poultry Power for Biochar Production

Kisebo Lantbruk AB are a family-run poultry farm in Sweden who have recently invested in biochar production technology to facilitate long-term sustainability in their farm operations while delivering significant added revenue. By combining their new Biomacon 'farm-edition' biochar reactor with Stronga FlowDrya equipment, the farm now co-generates renewable heat for their impressive poultry houses while producing high-quality biochar for soil improvement, diversifying their revenue streams.

Collaborating with Kisebo Lantbruk AB, Stronga have expanded our wood chip drying solutions into the Swedish market. Learn more about Kisebo's biochar production business below.

Sweden has, for a long time, been a global leader in renewable energy and circular bioeconomy solutions. With a strong forestry sector, they are well-positioned to scale biochar production; not only locking carbon into a stable form but also enhancing soil fertility and water retention at the same time.

The Climate Leap Swedish Government Program provides project-based investment aid to companies focused on reducing greenhouse gas emissions. More information on the scheme can be found here >

Balancing Heat Energy Requirements

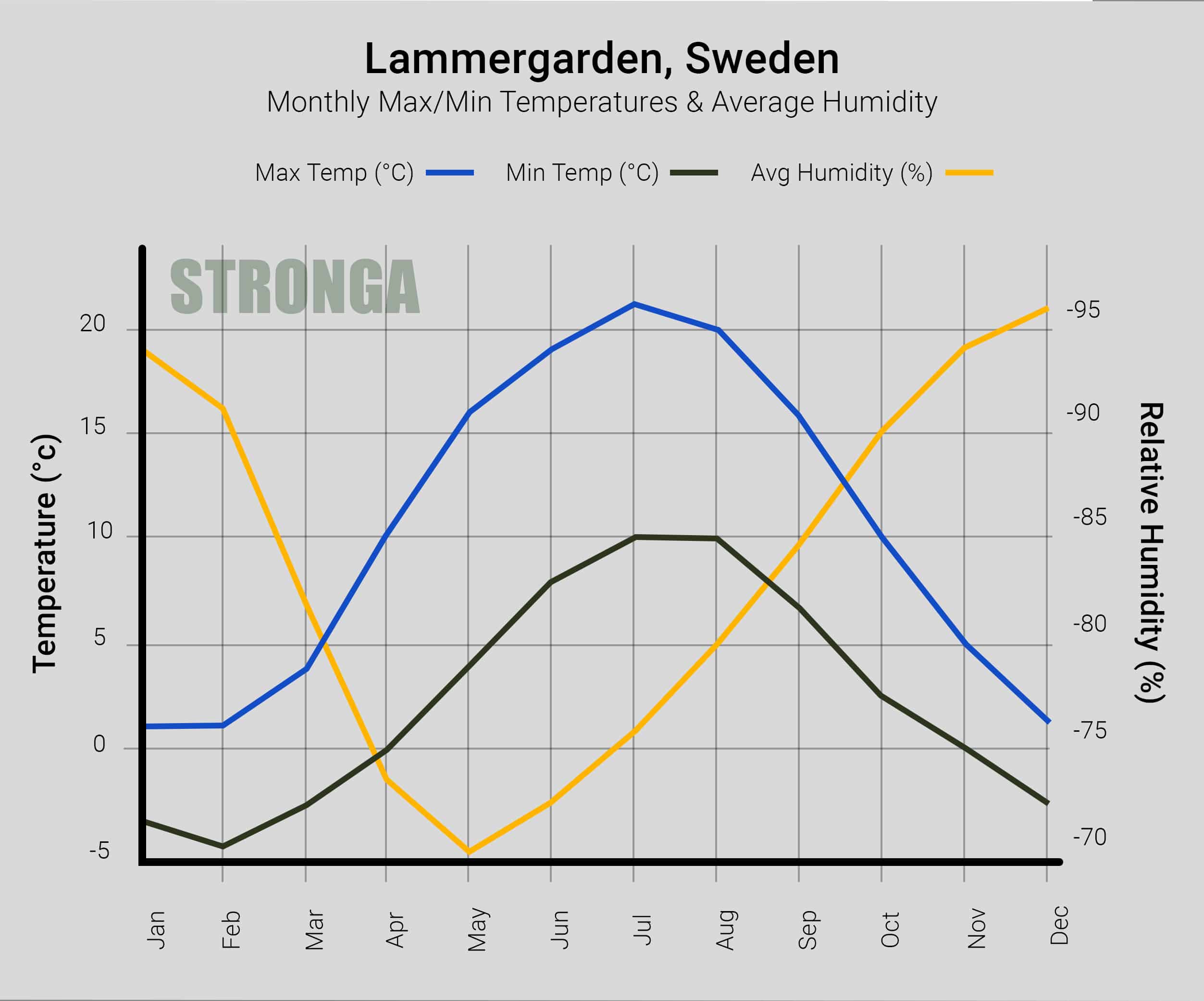

The hard-working team at Kisebo Lantbruk AB currently rear circa 250,000 broiler chickens on their farm in Lammergarden, Sweden. Heating is critical, particularly for the young chicks who require a warm and stable environment, year-round. The heat load is variable depending on the ambient weather and the chicken’s stage of growth. In Sweden’s cold winters (graph below), the energy demand can be significant.

Capturing and re-using all available thermal energy from the Biomacon biochar reactor is essential in making Kisebo’s business viable. This is why they recently turned to FlowDrya wood chip drying equipment to transform waste heat into a useful energy resource for biochar production.

Kisebo’s decision to invest in a biochar reactor as opposed to an LPG gas burner offers significant benefits, such as reduced carbon dioxide levels in the poultry house, less moisture and lower ammonia buildup; all contributing to overall better living conditions for chickens, improving growth and lowering risk of mortality.

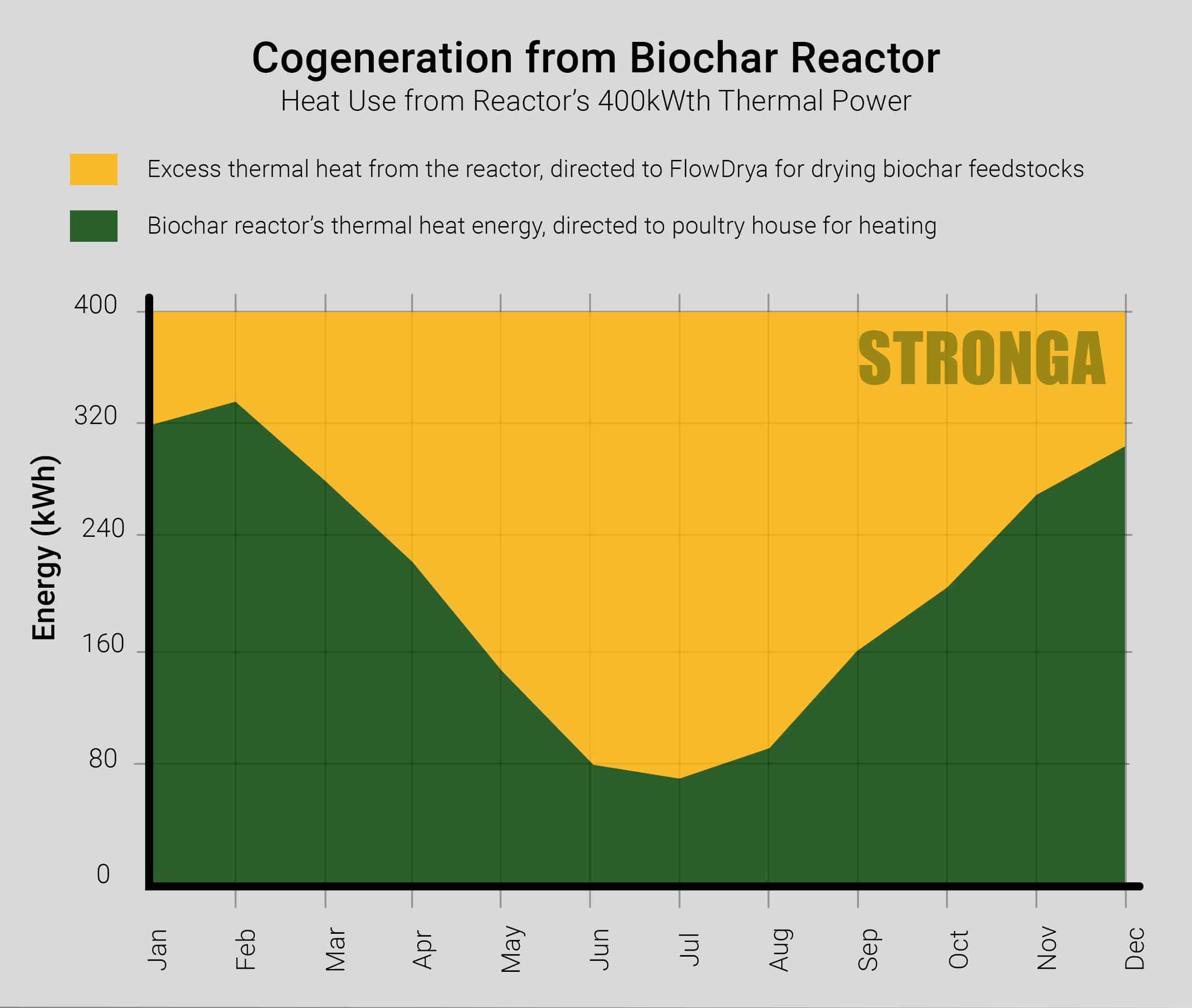

Kisebo Lantbruk invested in a Biomacon 400 biochar reactor capable of providing up to 400kWth of stable thermal energy in the form of hot water at 90°C, all year round. Seasonal heat load demand in the poultry house means residual heat can be utilised for a secondary application… drying the biochar feedstock. In the warmer summer months, all 400kWth is potentially available for drying woodchip. FlowDrya balances heat utilisation for the primary heat use, the poultry house; and secondary heat use, drying of the feedstock, so in total, all the heat is fully utilised. Nothing is wasted.

See below an example of what this could like for you. Please note that heat use varies according to weather conditions and poultry growth cycle. Our team are experienced in allocating energy where required. The chart below serves as a way to visualise the potential value from a cogeneration system like Kisebo’s; please talk to our team for bespoke advice.

Instead of wasting heat, Kisebo are now directing the variable, residual thermal energy to power the FlowDrya which offers a significant upgrade compared to their previous, thermally-inefficient container-based drying process which took 3-4 days to dry woodchips and involved expensive manual labour.

FlowDrya has the potential to be 3 times more efficient than hook-lift container drying – not only increasing the efficiency of process but also utilising the whole 400kWth of available heat load, as and when required. This dual-purpose process has increased the energy security and financial stability of the farm, allowing Kisebo to diversify their income streams and add further growth opportunities.

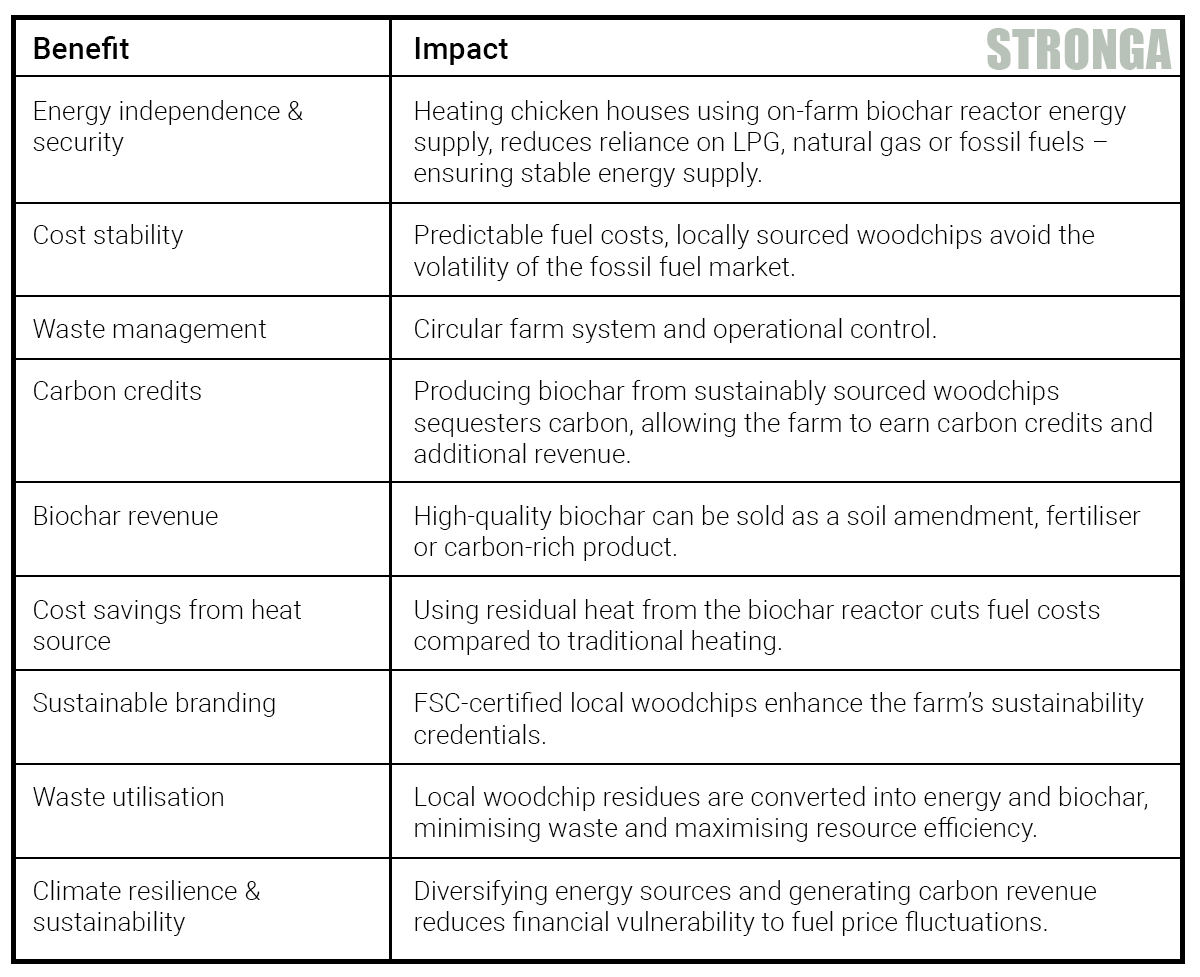

Benefits of On-Site Energy Supply

Biochar Production as a Secondary Application for On-Site Heat

Efficiently using all the thermal energy available means the farm now has the benefit of producing biochar in addition to their already successful poultry business. Biochar production brings with it carbon capture/storage opportunities, enabling Kisebo Lantbruk AB to join the carbon credit market as well as sell the bagged biochar (see below), derived from dry, FSC certified pine woodchip.

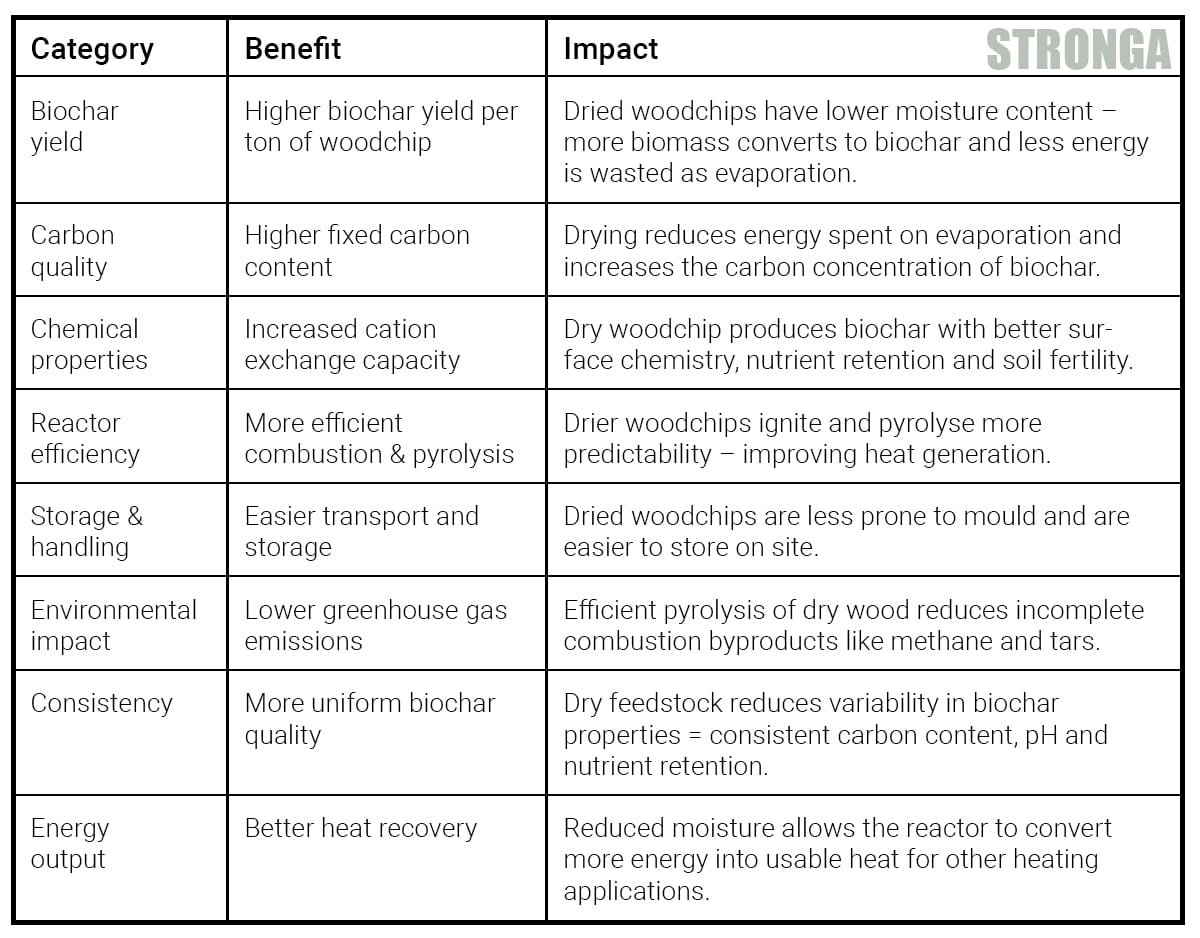

FlowDrya optimises biochar production, delivering dry, conditioned woodchip feedstock to the reactor. Learn the importance of drying biochar feedstocks in the table below.

Fostering meaningful, long-term engagement with our customers is central to Stronga’s values. Each wood chip dryer is made bespoke for the customer’s specific requirements; hand-crafted by our specialist engineers.

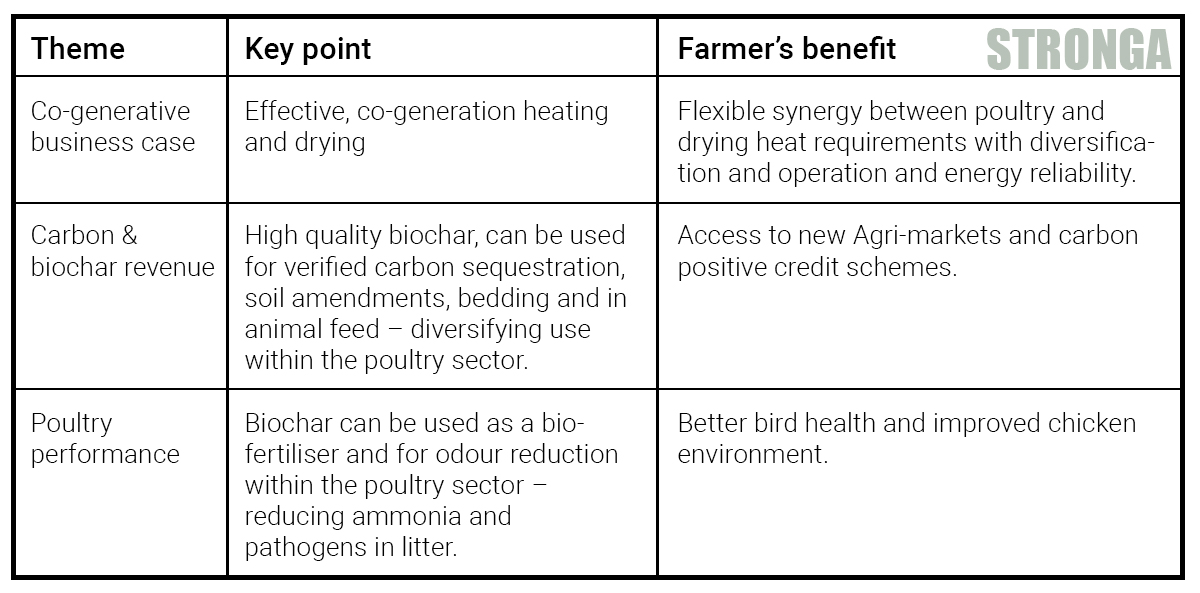

We are committed to providing a high quality, transparent service, during and after the installation of the Stronga equipment, building trust and delivering expertise, even after the equipment has been commissioned. By aligning our efforts with the customer’s, we were able to consider the several benefits offered by this co-generation project. Benefits of duality for FlowDrya integration + Biomacon 400:

By combining the use of their biochar reactor with FlowDrya, Kisebo has built a closed-loop, multi-output, energy and carbon solution. The approach reduces operational workload, delivers reliable poultry house heating, and produces valuable biochar. This proves to be a model for how biochar can be integrated into mainstream farming; not just as a soil amendment, but as a cornerstone of efficient, circular energy use.

From Vision to Value

Stronga are looking for similar, forward-thinking, entrepreneurs to continue our positive collaboration and explore new opportunities for efficiency, sustainability, and value creation. By partnering with individuals that share our vision, we can develop solutions that not only enhance performance but also address evolving environmental issues. All Stronga equipment is configured correctly for the customer’s requirements, in this particular case the dryer was successfully scaled to utilise the residual heat not required for poultry house heating.

We take pride in our products, knowing they have been expertly engineered and scaled with integrity; upholding the highest standards. Click here to view the Stronga FlowDrya product page for more information on the features and components of our equipment >

Contact Stronga today to begin your diversification project– enquiries@stronga.com

Share this post