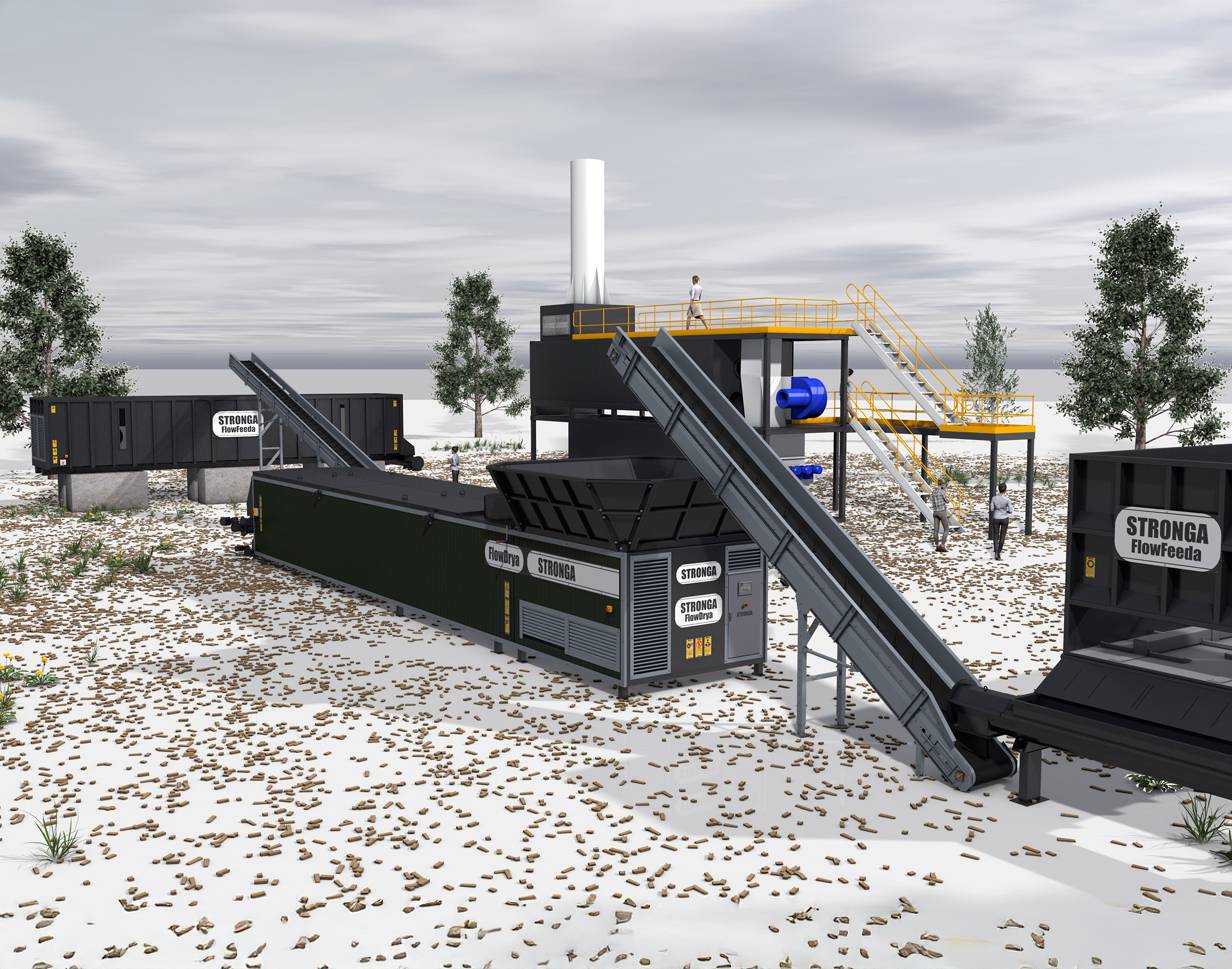

Stronga is proud to announce an exciting partnership with “IronChar Australia”, one of the country’s leading reclaimed and recycled hardwood timber specialists. Together, Stronga and IronChar have established a ground-breaking turnkey biochar production facility at IronChar’s “Pampoolah” headquarters in New South Wales, setting a new standard for biochar operations. The facility is visualised in the graphic below.

Utilising our expertise in sustainable materials and renewable energy technology, Stronga are now working with new prospects to deliver additional, fully integrated biochar production projects in Australia and beyond. Learn more.

Step Toward Integrating Australia’s Timber & Bioenergy Sectors

Stronga’s recent collaboration with IronChar Australia has been seamless, with IronChar’s commitment to responsible timber recovery complementing Stronga’s expertise in drying biomass. At IronChar’s “Pampoolah” headquarters, the coordinated system is now operational, transforming reclaimed hardwood residues into premium-quality activated carbon with carbon content beyond 90%.

This project represents a significant step toward closer alignment between Australia’s timber and bioenergy sectors. It demonstrates how modern biochar feedstock drying and pyrolysis technologies can accelerate carbon reduction while dramatically improving resource efficiency.

Working alongside environmental process engineers and an established pyrolysis manufacturer, Stronga delivered a fully integrated turnkey system for IronChar - combining drying, feeding, and pyrolysis equipment to produce premium-quality biochar. The highly automated process offers the benefits of extremely low labour costs and manual material handling, providing a streamlined solution that turns biomass by-products into high-value outputs, including biochar, carbon credits and premium soil improvers.

Learn more about Stronga’s turnkey biochar production systems >

Packaged Biochar Production Solutions

Clients partnering with Stronga benefit from a streamlined setup process that covers complete system design, integration, commissioning, and more - making it easy for businesses to adopt new technology and operate with confidence.

Our team of experts evaluates all project-specific variables to ensure the drying and feed system for biochar production is fully optimised. We assess the characteristics of the wet feedstock, required throughput, local climatic conditions and other critical factors. The result is a purpose-built drying and feeding solution that consistently delivers optimal results in biochar production.

The graphic below illustrates the biochar production solution Stronga delivered on time and within budget for IronChar Australia. Proven, reliable, long-life equipment has been strategically arranged to minimise labour costs through intelligent controls and other automation systems, including conveyors and long-life discharge augers.

Bespoke Feed Systems for Biochar Feedstocks

For the IronChar collaboration, Stronga customised the FlowFeeda biomass feeder with mobility features. By mobilising the typically static FlowFeeda, operators can fill woodchip at the chipper site, eliminating the need for repeated loading intervals.

Once transported back the Pampoolah site, FlowFeeda easily connects to a stationary hydraulic and electrical station, streamlining operations and drastically reducing expensive labour costs. This integration enhances efficiency and ensures reliable feeding of the biomass dryer, optimising the overall biochar production process.

The video below shows the 2-no. mobile FlowFeeda units sold to IronChar Australia.

Complete Systems for Biochar Production

Working together with organisations like IronChar Australia, Stronga are setting a new standard for circular biomass operations, transforming biochar feedstocks into clean, premium biochar while helping businesses add real value to their operations. We can offer complete biochar production solutions tailored to your needs, reach out to us at enquiries@stronga.com to learn more about the following products.

• FlowDrya – biochar feedstock drying systems >

• FlowFeeda – continuous feed systems for biomass materials >

• HookLoada – multi-functional hooklift trailers designed for biomass transport applications >

• Pyrolysis reactor units – Stronga works together with the client to recommend the optimum pyrolysis manufacturer and product, who we believe have the correct capabilities and solutions.

Share this post