1.9 Gigatonnes of CO₂e Annually

Peat has long been a staple in horticultural substrates due to its favourable properties; high water retention, soil structure improvement and nutrient availability, to name a few.

Peat extraction, however, is destructive and harmful. It is associated with environmental degradation, habitat destruction and the release of harmful carbon emissions. The ‘International Union for Conservation of Nature’ confirmed that approximately 5% of anthropogenic global greenhouse gas emissions are derived from damaged peatlands. The ‘Wildlife Trusts’ report states that, by using peat, ‘gardeners and food growers in the UK may have released as much as 31 million tonnes of carbon dioxide into the atmosphere since 1990’.

Peat extraction is unsustainable and while preserving peatlands becomes a priority, with peat regulations already in circulation – the horticultural industry is focussed on finding sustainable alternatives.

Biochar-Breakthrough in Peat-Free Growing

Biochar is fast becoming recognised as a sustainable alternative to peat with research indicating that incorporating it into substrates improves soil microbial communities, as well as enhances plant growth, water and nutrient retention. Biochar’s nutrient and cation exchange qualities, high surface area, ability to reduce nutrient leaching and absorption qualities, is proven to improve existing growing substrates.

The result of this is significant soil enhancement, boosted crop yields and reduced environmental pollution from pathogenic microorganisms, heavy metals and pesticides. Expert, Henrique Natalli, believes that biochar can positively affect the physiochemical properties and nutritional characteristics of substrates, making them better equipped to compete with the qualities of peat.

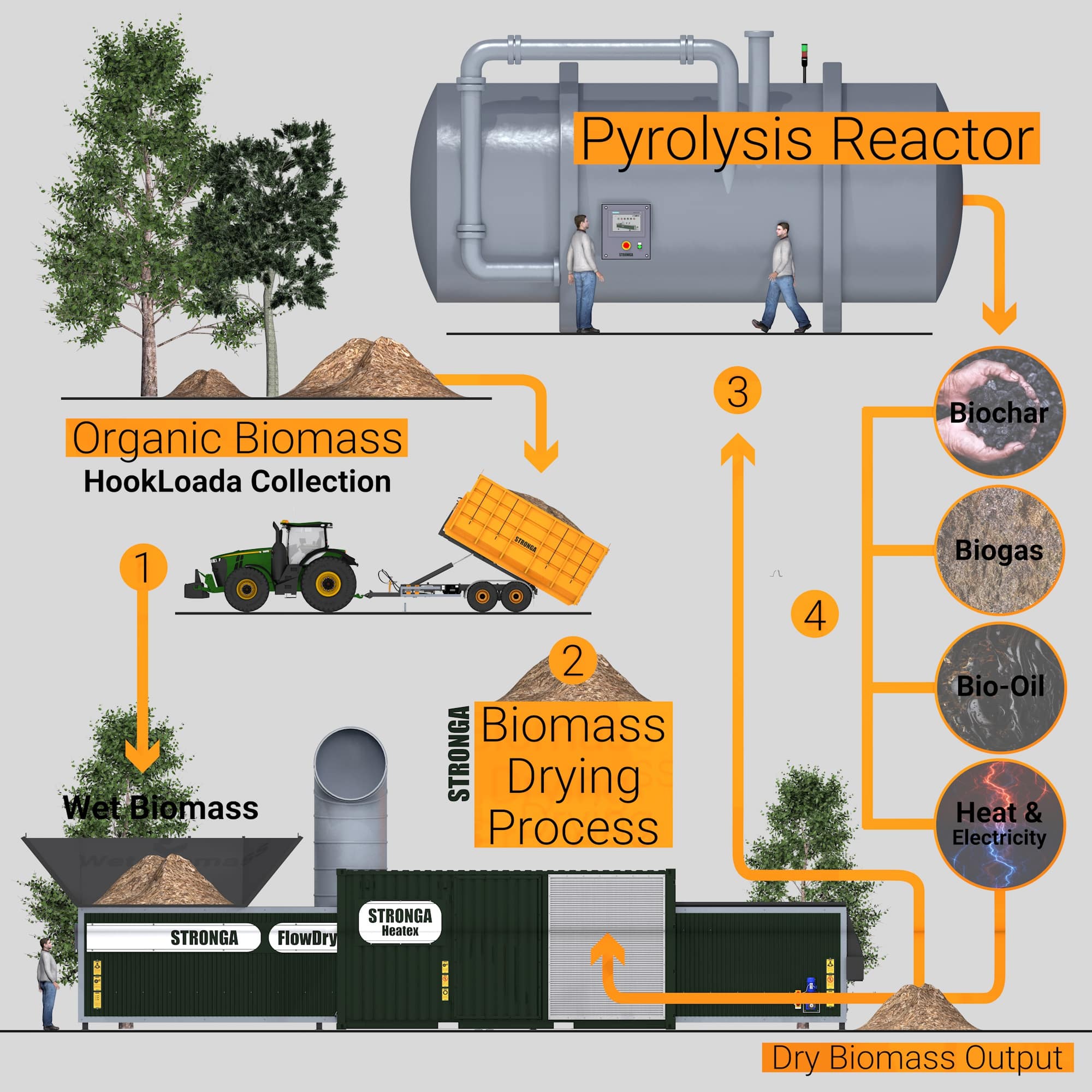

Produced by pyrolysis using organic residues and waste, the production of biochar material itself is already more sustainable than peat production and extraction. As well as being used in growing substrates, it is also able to store carbon in soil for centuries – reducing greenhouse gas concentrations to help mitigate climate change.

The benefits are extensive.

FlowDrya Enhances Biochar’s Brilliance

While biochar’s restoration qualities can help improve growing substrates and plant growth potential, using low moisture feedstocks for the pyrolysis process remains highly important for successful and efficient production.

High moisture feedstocks are renowned for causing a multitude of problems during pyrolysis, including flash boiling which occurs when the feedstock is too wet. The internal water rapidly vaporises under extreme heat during pyrolysis, sometimes causing violent expansion and an influx of steam pressure. Pre-drying biochar feedstocks using Stronga FlowDrya equipment can;

• Reduce reactor faults, malfunctions and machine clogging

• Improve structural integrity and char quality

• Improve fuel efficiency during the pyrolysis process

• Improve the combustion quality of the feedstock in the pyrolysis reactor

The graphic below demonstrates where the FlowDrya feedstock-drying process fits into premium biochar production.

Biochar Enhances Crop Growth; Here’s Proof

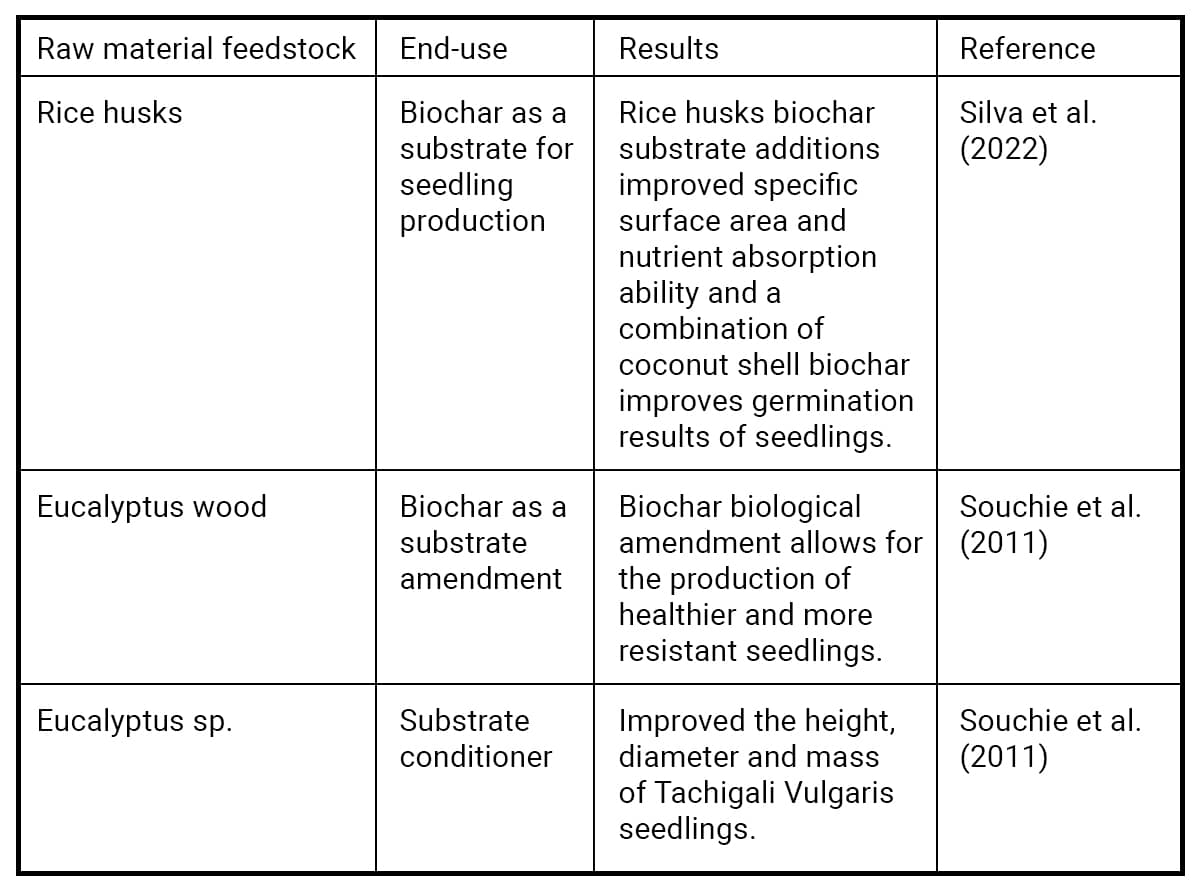

Research across a wide range of publications has proven that biochar improves growing conditions for plants on many levels including, growth, root length and leaf area, similar to as if they were grown in peat. Unlike peat, biochar does not contribute to the release of stored carbon and also has the ability to minimise nematode and weed infestation.

The results below have been extracted from Natalli’s research:

Key Benefits of Biochar in Growing Media

1. Enhanced Water Retention & Aeration - reduces the need for frequent irrigation, making it a valuable solution in water-stressed environments.

2. Improved Nutrient Availability - enhances cation exchange capacity, leading to improved nutrient retention and availability for plants.

3. Microbial Community Enhancement - beneficial microbial activity, contributes to healthier root development and increased plant resilience against pathogens, supporting improved plant health and growth consistency.

4. Reduction of Peat Dependency - biochar reduces the environmental footprint in the horticultural and forestry sectors.

The Art of Making Good Decisions…

FlowDrya creates added value for businesses in the horticultural sector, drying biomass feedstocks for high-quality biochar production. As peat continues to be phased out, biochar represents a long-term, carbon-conscious alternative. Be part of the transition today – enquiries@stronga.com

This article was written using information from the following sources:

Baronti, S., Montagnoli, A., Beatrice, P. et al. ‘Above- and below-ground morpho-physiological traits indicate that biochar is a potential peat substitute for grapevine cuttings nursery production’. Scientific Reports 14, 17185 (2024). Link here >

Henrique Natalli, L., Everton, H., Lombardi K, C., Marcelo G,. Remigio N,P. ‘Use of biochar as a component of substrates in horticulture and forestry: A review’ (2024). Link here >

Yu, P., Qin, K., Crosby, K. et al. ‘Biochar reduces containerized pepper blight caused by Phytophthora Capsici.’ Sci Rep 14, 30664 (2024). Link here >

Share this post