What is the Black Soldier Fly (BSF)?

Black Soldier Fly, or Hermetia illucens, is becoming farmed at increasing rates worldwide, primarily for the production of protein and animal feed, but also because it involves the recycling of a useful organic waste.

How does the Black Soldier Fly support the circular production of bio-fertiliser?

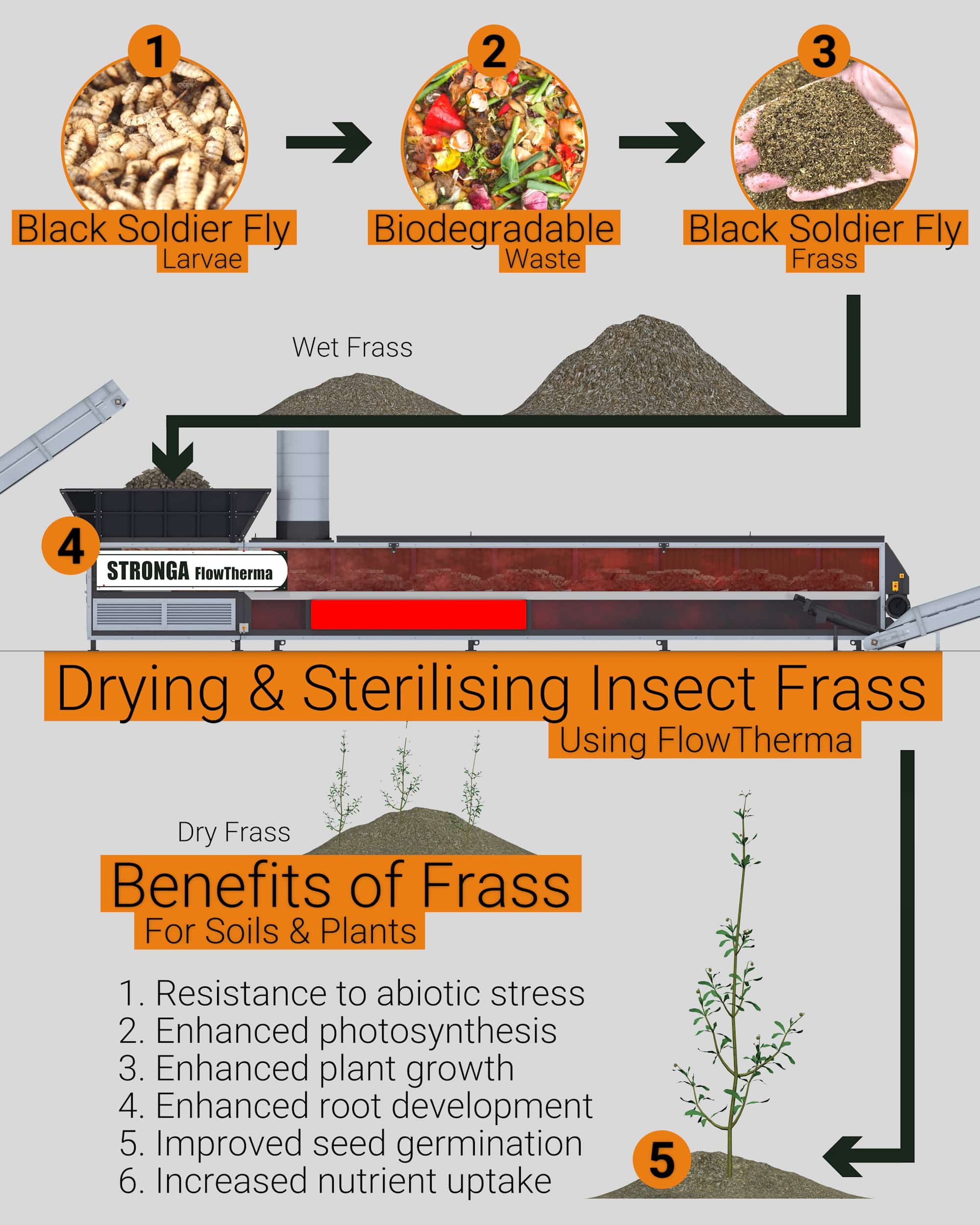

The larval stage is key for fertiliser focused production. The BSF’s larvae are rich in nutrients and can break down organic waste into useful frass by-products. The paragraph below details the typical process of BSF farming.

(1) Growing BSF; (2) Production of BSFL (Black Soldier Fly Larvae); (3) Larvae consumes food/organic waste (of which up to 40% of food is wasted globally); (4) Converts waste into nutrient-rich material frass (manure); (5) Larvae is separated from the frass - Outputs are insect protein (animal feed) + frass (fertiliser); (6) Frass available for pasteurisation and pelleting using FlowTherma, for sale as fertiliser.

Why are Black Soldier Fly larvae increasingly popular in sustainable farming?

BSFL are particularly efficient at transforming food, agro-industrial by-products, manure and other organic waste streams into high-value products (animal feed and nutrient rich fertiliser), supporting circular economy systems and reducing reliance on chemical fertilisers.

What is “frass” and how does it relate to Black Soldier Fly fertiliser production?

“Frass” is the combination of insect excrement, leftover feedstock and larval casings. The dead farmed insect content should not be more than 5% in volume and 3% in weight, as per Commission Regulation (EU) 2021/1925.

BSF frass is rich in beneficial nutrients, bacteria and micronutrients, making it an excellent soil amendment, contributing to overall plant quality and health. Having similar qualities to compost, frass can be upcycled as a fertiliser. It has gained recognition in recent years as a result of successful income generation in the agribusiness sector.

What nutrients do Black Soldier Fly frass contribute to soil health?

BSF fertiliser is a natural source of nitrogen, phosphorus, potassium (NPK) and chitin — a biostimulant known to support soil/plant health and stimulate plant defences. Not only does the frass contain fewer pathogens than alternative animal manures, it is also significantly more carbon-rich when compared to other fossil fuel-based fertilisers.

Nitrogen (N) - Supports leaf and stem growth via enhanced chlorophyll production

Phosphorus (P) - Macronutrient vital for root development and flowering

Potassium (K) - Enhances fruit quality, helps regulate water use and disease resistance

Micronutrients - Such as zinc, magnesium, and trace elements, boost overall soil health and plant vitality

Why is Black Soldier Fly frass being used increasingly in farming?

Meticulous Research’s Global Edible Insects Market Forecast report states that the insect farming industry is growing rapidly, projecting it be worth approximately $18 billion by 2033. But why?

BSFL is seen in the farming sector as a more sustainable alternative to chemical fertilisers, reducing the increasing accumulation of global organic waste and greenhouse gas emissions. Sitting at the intersection of waste management, nutrient recycling and soil health – BSFL is an efficient way to upcycle low-value organic waste (food waste, manure, crop residues) into high value products (proteins and frass). It can help reduce methane emissions and landfill use, acting as a bio-stimulant to improve plant health and soil structure.

How does Black Soldier Fly frass fertiliser compare to traditional compost or manure?

BSFL fertiliser is often more nutrient-dense, faster-acting and less odorous than traditional manure. It also tends to be more consistent in composition. Unlike traditional compost or manure, BSFL fertiliser has a faster production cycle. It contains partially-digested organic matter which is easier for plants to absorb.

The United States Department of Agriculture and the University of Arkansas both concluded, in testing, that insect frass had a hugely positive effect on crop yields and soil fertility.

What are the main benefits of insect frass for soil/plants?

BSF frass has been proven to enhance microbial activity, support beneficial bacteria, improve soil aeration and increase water retention capacity. The benefits on soil and plants include:

1) Enhances microbiological activity, carbon content and organic matter in soil

2) Improves water holding capacity of soil

3) Introduces microorganisms and biomolecules into soil

4) Increases plant resistance to abiotic stresses (drought/flooding)

5) Improves pathogen resistance

6) Introduces micro and macro nutrients into soil

Why is using Black Soldier Fly larvae for fertiliser considered environmentally-friendly?

BSFL allows for the upcycling of organic waste that would otherwise decompose and release greenhouse gases. It also reduces landfill burden by converting waste into valuable, useful fertiliser products. By transforming waste into nutrient-rich biomass fertiliser, BSFL helps recycle nutrients back into the soil, creating a circular farming economy.

Can Black Soldier Fly fertiliser help reduce reliance on chemical fertilisers?

Yes. BSF fertiliser can significantly reduce the usage of chemical fertilisers by providing essential nutrients like nitrogen, phosphorus and potassium - naturally. While it may not match the immediate nutrient spike of synthetic fertilisers, BSF fertiliser supports long-term soil fertility and sustainability in agriculture.

Which crops benefit most from Black Soldier Fly larvae fertiliser?

BSFL fertiliser benefits a wide range of crops, including vegetables (tomatoes, peppers, lettuce), fruits (strawberries, bananas, citrus), cereals (corn, wheat), and even ornamental plants. It is especially effective for nutrient-demanding crops because it gradually releases nutrients, supporting steady growth and improved yield.

Can Black Soldier Fly larvae fertiliser be pelleted and stored?

Yes, BSFL fertiliser can be pelleted and stored if kept dry, cool and airtight. As frass is typically so light, pelleting it helps increase the density of the material.

Under proper storage conditions, dried and pelleted frass can last approximately 6–12 months without significant nutrient loss. High moisture levels or improper storage can lead to mould growth or nutrient degradation, so drying down to a suitable moisture content is important, typically circa 12% moisture. High moisture in the larvae frass pellets creates ideal conditions for mould and bacterial growth.

Stronga FlowTherma equipment offers drying and heat treatment in one pass, eliminating the conditions in which bacterial growth and product degradation typically occur, improving the product’s preservation for storage and pelleting whilst removing pathogens and improving the quality of fertiliser.

Can wet BSF frass be used for pellet production?

No, wet frass is unsuitable for direct pellet production. High moisture content, circa 60%, makes grinding difficult, and the resulting pellets do not bind, are prone to spoilage, and likely to harbour bacteria or mould. Drying down to 12% moisture content is a necessary step in producing stable, long-life pellets. Low moisture ensures firm, durable pellets with consistent nutrient content and storage stability, optimising the commercial value. Drying frass significantly improves the onward value of the product.

What regulations exist around using insect-derived fertilisers in agriculture?

Regulations vary by country but many regions now recognise insect frass as a legal organic fertiliser. However, producers must follow biosecurity and waste-processing standards subject to that region.

Since 2021, EU regulations have defined the standard requirements for marketing insect frass as organic fertiliser. Frass must undergo a minimum heat treatment of one hour at 70’C before being eligible for sale within EU member states, subject to national authorisation. This step is crucial for its acceptance into markets and pasteurisation of any pathogenic microorganisms.

What are the main benefits of drying & pasteurising Black Soldier Fly Larvae frass?

Thermal treatments of 70’C for one hour allow insect frass to become both a standardised and stable product. This is necessary for use in specialised markets and for adoption in the EU. If BSFL frass is to be pelleted and sold as fertiliser – drying, in addition to the regulatory thermal heat treatment, offers multiple benefits.

| Benefit | Impact | How Drying & Pasteurisation Contribute |

| Pathogen Safety | Produces safe, bio-secure fertiliser/pellets suitable for all farming systems. | Heat treatment kills harmful bacteria, fungi, and parasites. |

| Moisture Control & Stability | Prevents spoilage, mould growth, and microbial regrowth. | Drying lowers the moisture content to >12%, stabilising the product, making it suitable for pellet production. |

| Nutrient Retention | Maintains NPK, chitin, and other nutrients for effective soil enrichment. | Controlled drying preserves nutrients; sterilisation prevents microbial loss. |

| Extended Shelf Life | Allows storage and transport without frass degradation. | Drying frass removes the moisture environment in which bacteria thrives, resist decomposition and secondary microbial growth. |

| Ease of Handling & Pelletisation | Enables consistent, free-flowing frass suitable for pellets or spreading. | Drying improves material handling and processing; pasteurisation ensures microbial stability. |

| Odour Reduction | Improves usability in urban or greenhouse applications. | Heat treatment reduces odour-causing microbial activity. |

| Consistency & Quality | Standardised moisture and microbial profile for predictable fertiliser quality and sale within the EU. | Drying ensures uniform moisture; pasteurisation ensures uniform safety. |

What makes the FlowTherma frass dryer & pasteuriser the most capable machine in the market?

The Stronga FlowTherma is a dual-purpose, dry heat, dryer and pasteurisation system. Thermal treatment and drying ensures combined moisture removal and pathogen removal, allowing producers to comply with EU regulations.

Designed to handle low bulk density BSFL frass, FlowTherma aids in the transformation of waste into a marketable pellet product, drying, densifying and pasteurising the material. With material depth control and a semi-autonomous operation, process efficiency is delivered and expensive labour requirements are minimised.

DryStation™ HMI controls and data logging allow operators to target specific heat-treatment requirements, evidencing certification for insect frass EU distribution. What’s more, the FlowTherma is designed to optimise the use of any residual heat available, making it a highly energy-efficient process.

What pathogens does the FlowTherma solution remove?

Common pathogens hosted by Black Soldier Fly larvae are Escherichia coli (E. coli) and Staphylococcus spp. - most often found in their frass. The 70’C, one-hour FlowTherma treatment cycle has been proven to remove both of these, as well as the risk of Salmonella spp. through the reduction of Enterobacteriaceae via thermal pasteurisation.

How does FlowTherma’s PulseWave™ system enhance drying & pasteurisation?

FlowTherma’s unique PulseWave™ agitation system thoroughly mixes and agitates the BSF frass material on the hydraulic moving floor, ensuring that the entire load is uniformly heat treated to specific time at temperature requirements.

Material agitation allows for a consistent conductive heat flow through the material, reducing overdying risks while optimising the thermal treatment process, ensuring even drying and pasteurisation of the entire load.

Can FlowTherma be customised to suit specific drying needs?

Each FlowTherma is designed with the customer’s individual project parameters in mind and scaled to throughput requirements, allowing customers to meet market needs.

Stronga’s experienced engineering team consider various parameters including; material moisture content, material characteristics, local climatic conditions and any regulatory requirements when scaling the FlowTherma. This means each unit is fully optimised for the client’s unique circumstances.

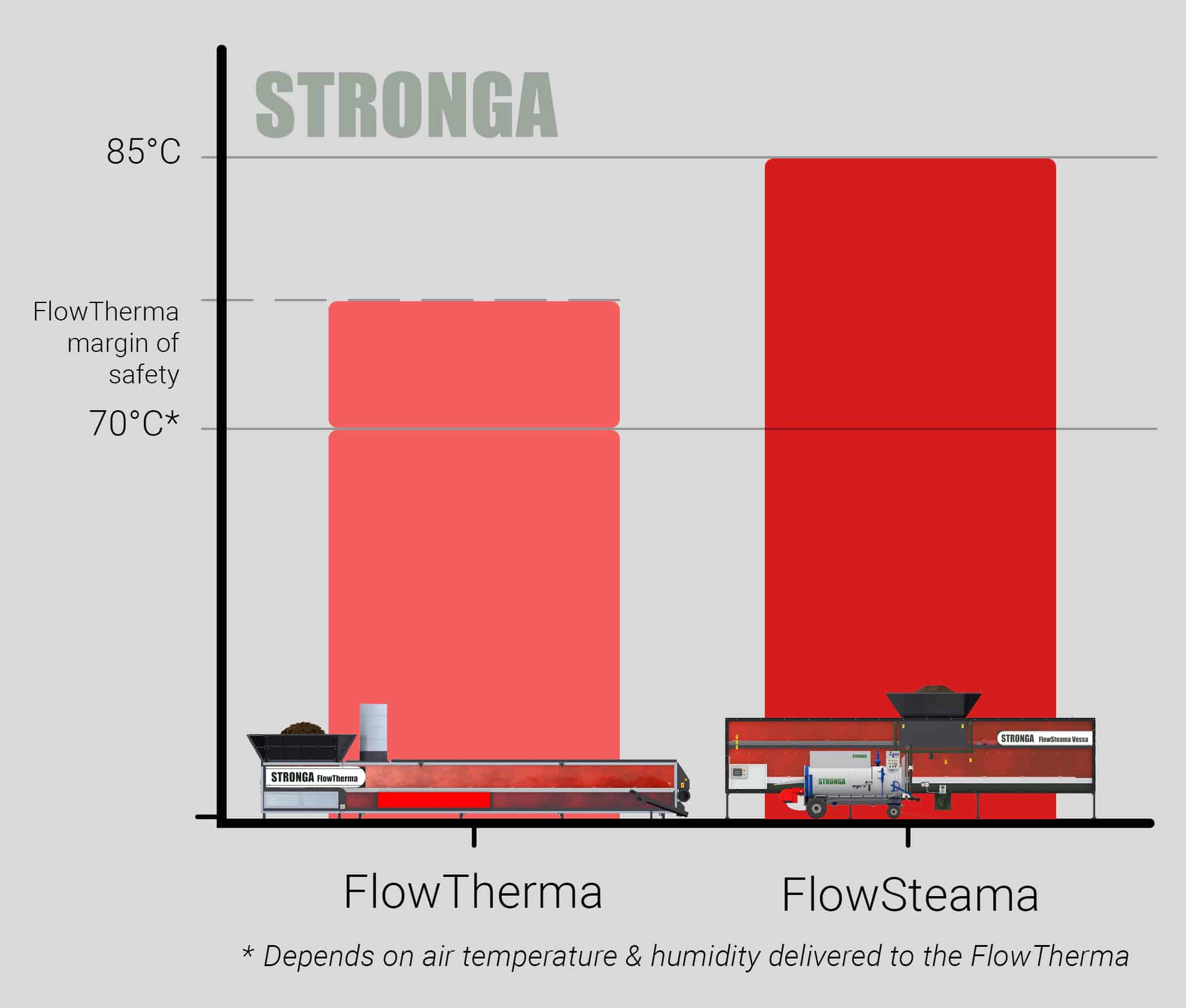

How does FlowTherma differ from Stronga’s single-purpose steam sterilisation equipment?

FlowTherma is a dual-purpose machine from a similar single-pass design.

FlowTherma uses a specific air flow temperature to heat treat and dry the input material whereas FlowSteama uses super-heated 200’C, steam to pasteurise the input material (frass). This adds additional moisture to the insect frass. Where customers require heat treatment and drying, in the production of insect frass pellets for example, FlowTherma offers the desirable 2-in-1 solution, heat-treating up to and beyond 70’C.

At Stronga, we help guide customers onto success, allowing them to reach lasting prosperity. We love finding projects that add real value and support sustainable farming, like this project we delivered to dry and heat treat Black Soldier Fly larvae. It is a living cycle where food becomes resource, resource becomes growth and growth sustains.

You too can create meaningful change with Stronga. Let us share, listen and build - ensuring no efforts are wasted. For more information on the specific requirements for your insect frass project, speak to our team today: enquiries@stronga.com

Trusted by visionaries. Built for results. Engineering the future through sustainable value creation.

Share this post