Traditionally, wet bark by-products produced by sawmills have been treated as a low-value by-product. However, with increasing demand for landscaping materials, dried bark fractions now represent a valuable, revenue-generating commodity that should not be overlooked.

By investing in Stronga FlowDrya bark drying equipment, sawmills can add significant value to their bark by-products, unlocking substantial financial gains, while diversifying revenue streams. Learn more below.

Utilising Residual Heat

Sawmills not only have an abundant supply of bark by-product; they are also equipped with biomass boilers for kiln operations - a significant capital investment that is already in place. With access to low-cost wood residues as fuel, these businesses are well-positioned for energy-efficient kiln drying operations. On-site kiln operations do not require continuous heat load, enabling the existing boiler capacity to be strategically leveraged to enable additional bark drying processes, utilising surplus thermal energy capacity.

FlowDrya is modular and can be easily integrated into existing operations, to produce high value bark products from the existing on-site infrastructure. FlowDrya equipment can be configured to match the throughput required, spare heat availability and other on-site requirements. Through drying, sawmills gain access to the growing premium markets that require dry bark, this includes nurseries, landscaping businesses, garden centres and more. This allows sawmills to diversify their revenue stream and add stable income from dry bark that can be sold year-round.

FlowDrya Directly Increases the Value of Bark

Using FlowDrya equipment, dried bark can be efficiently processed and separated into different saleable fractions. This allows for higher-quality end products, more consistent particle sizes and higher % rates of separation. The FlowDrya process is unique in that it aids effective screening and separation of high value microchips from the main bark material, and also via sub floor screening, is able to remove soil, dirt and other unwanted materials from the high-quality bark material.

This fraction separation capability offers huge benefits for sawmills.

Dry bark enables:

• Increased saleable value per m₃.

• More effective screening and processing.

• Higher yields of clean, uniform bark fractions.

• No microbial degradation, odour and/or moulding.

• Better long-term storage and consistently available bark inventory.

• Reduced clumping and higher flow rates per m₃ through equipment.

• Better blending properties for horticultural and landscaping requirements, including in compost and biochar blends.

FlowDrya Lightens the Load

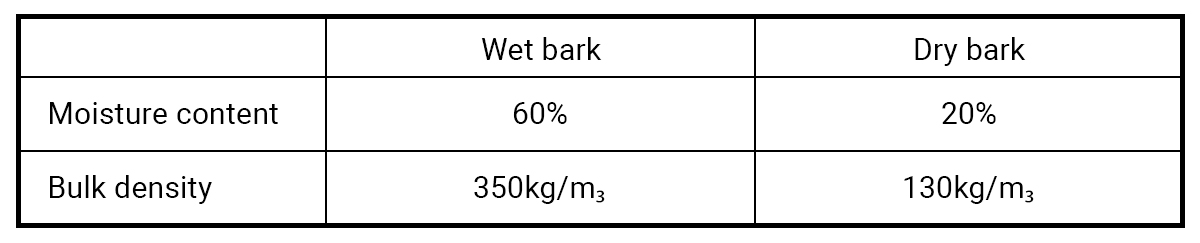

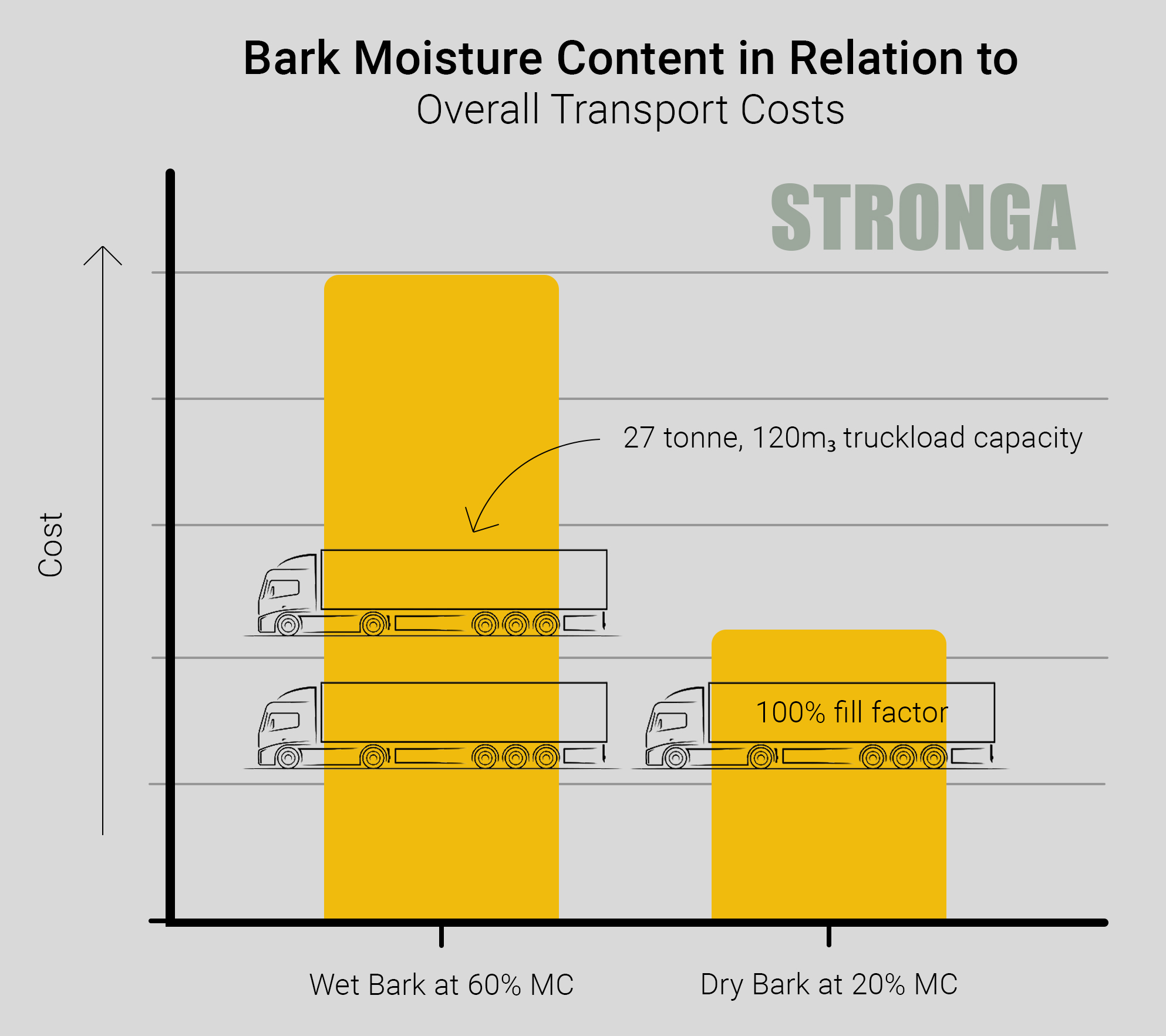

In addition to the vastly improved fraction separation percentage rates, dry bark is also considerably lighter than wet, as shown in the table below. Through drying, FlowDrya increases profit potential per truckload, as moisture removal = lower weight of bark = more bark product hauled per truckload + less fuel used per tonne transported.

The Business Case

Fresh bark with a moisture content of 60-65% typically has a bulk density of circa 350-420kg/m₃*. In Europe, the maximum payload for a 3-axle artic lorry is approximately 27 tonnes, meaning the truck could only carry 77m₃ of wet material. The higher the moisture content of the bark, the less material can be transported in one truckload – this means more loads, more trucks, more fuel and more labour… all of which are only increasing in price due to inflation.

FlowDrya is able to reduce the moisture content of bark down to 20%, therefore the weight significantly reduces to approximately 130kg/m₃, enabling the full load to be transported in one truck. These transport savings really add up.

Wet bark: 120m₃ truck capacity x 350kg/m₃ wet bark = 42-ton overall load weight. More than one artic truck required.

Dry bark: 120m₃ truck capacity x 130kg/m₃ dry bark = 15.6-ton overall load weight. Less than one artic truck required.

* Dependent on tree species - Cork, Periderm, Phloem etc.

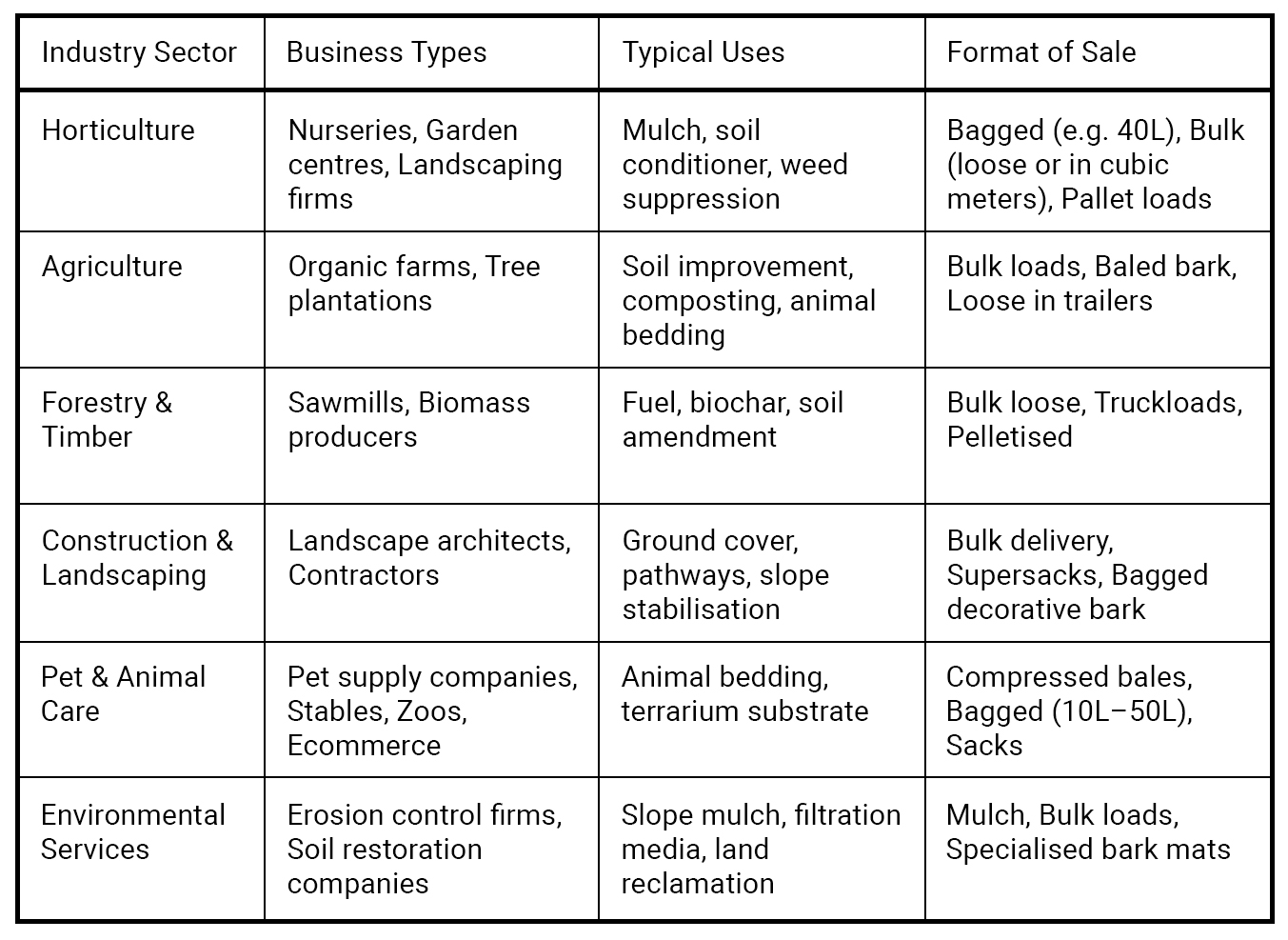

Dry Bark Applications, Uncovered

The landscaping sector requires consistent, clean and lightweight bark which is less likely to compact, is easier to apply and has a better overall aesthetic appearance. What’s more, dry bark also contributes to better weed suppression, water retention, aeration and soil insulation. Dry bark applications are summarised in the table below.

FlowDrya’s unique PulseWave™ agitation system mixes and tumbles the material on the drying bed, ensuring the output bark load is consistently dry, increasing its market value.

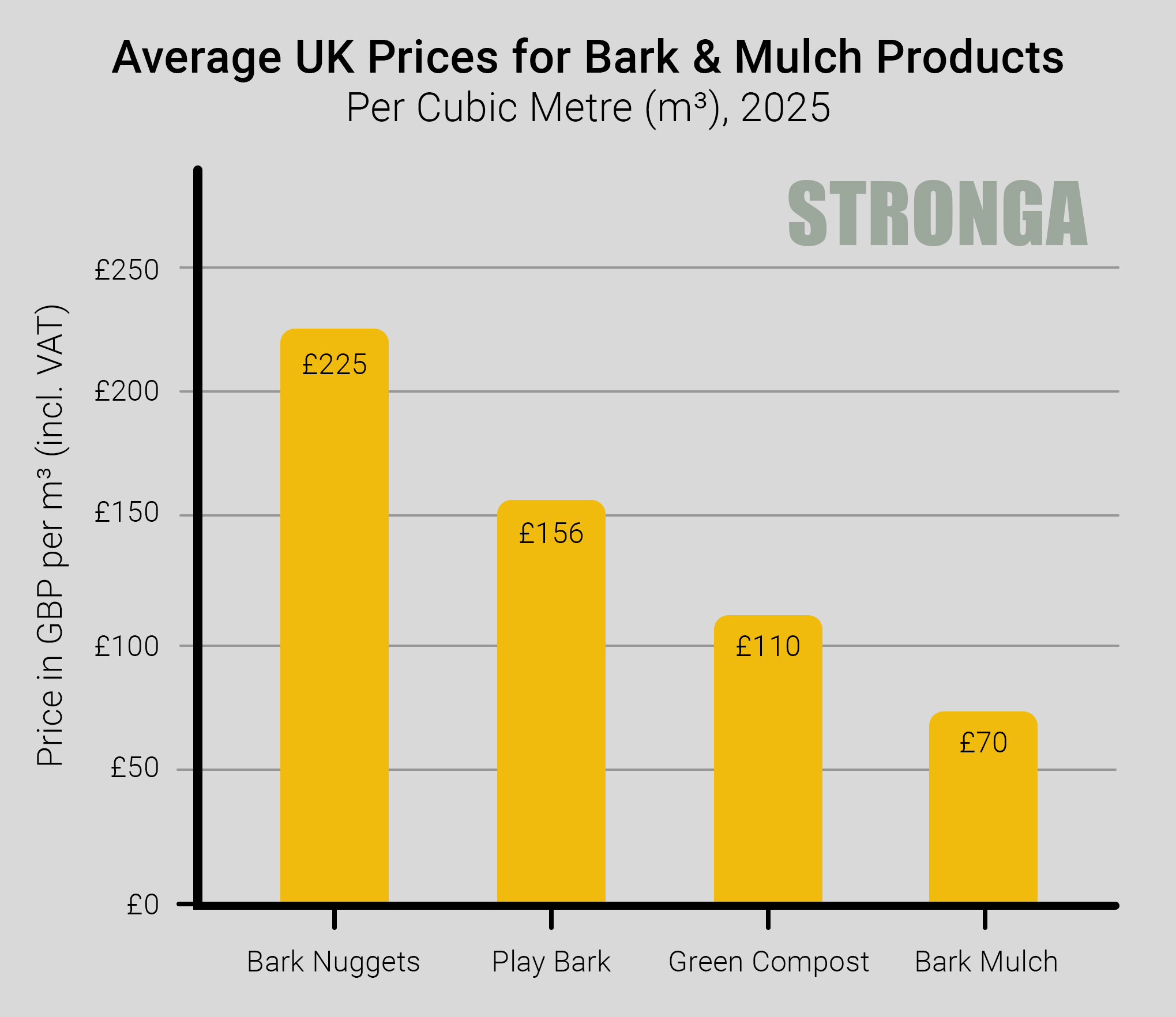

Discover where the value lies in the various, saleable dry bark and mulch fractions. The graph below is based on 2025 average UK market prices. Prices are per cubic metre (m³), based on bulk loose or bagged quantities (approx. 1 m³ = 1,000 L).

Ornamental bark nuggets typically have the highest commercial value and decorative landscaping is one of the most common applications for dry bark. Bark nuggets help retain soil moisture, suppress weeds, insulate plant roots and deter pests, while their durability and natural and uniform appearance enhances their visual appeal.

Dry play bark chips are a low maintenance option that can be used as a soft, impact-absorbing surface for playgrounds. These are usually tested against safety standards (BS EN 1177) before application.

Composted bark or “green compost” can be added to soil blends as a peat-free alternative, to improve the structure, aeration and drainage of the soil.

Bark mulch can be used for landscaping and for soil conditioning and horticultural purposes. When bark decomposes in soil, it introduces organic nutrients into the soil, supporting the growth of healthy plants. Mulch is available in coarse, medium and fine grade standards.

FlowDrya Optimises Bark Drying Potential

Energy efficient bark drying equipment ✔ Continuous bark drying process ✔ Uniform drying; consistently dry output ✔ Modular; able to be positioned in or outside ✔ Low labour costs with automatic operation and a large infeed hopper ✔ & more…

Click the link to Stronga FlowDrya Green Series web page to learn more >

Get in touch with our friendly team today to discuss your bark drying requirements - enquiries@stronga.com. Need to meet bark phytosanitation rules and remove moisture? Stay tuned to learn more.

Share this post