This article has been adapted from the following paper:

Shams Forruque Ahmed, Fatema Mehejabin, Ashfaque Ahmed Chowdhury, Fares Almomani, Nadeem A. Khan, Irfan Anjum Badruddin, Sarfaraz Kamangar ‘Biochar produced from waste-based feedstocks: Mechanisms, affecting factors, economy, utilization, challenges, and prospects’, (2024: GCB Bioenergy). Source article here >

Biochar 101

Produced by the process of pyrolysis, biochar is a porous, carbon-rich material which has extremely high adsorption and ion exchange capacities. Unlike other organic materials, the central benefit of biochar is that it resists decomposition, meaning it is capable of locking-away carbon over many centuries. Of late, biochar has become a cornerstone in sustainable agriculture practises, as well as in carbon sequestration and environmental remediation.

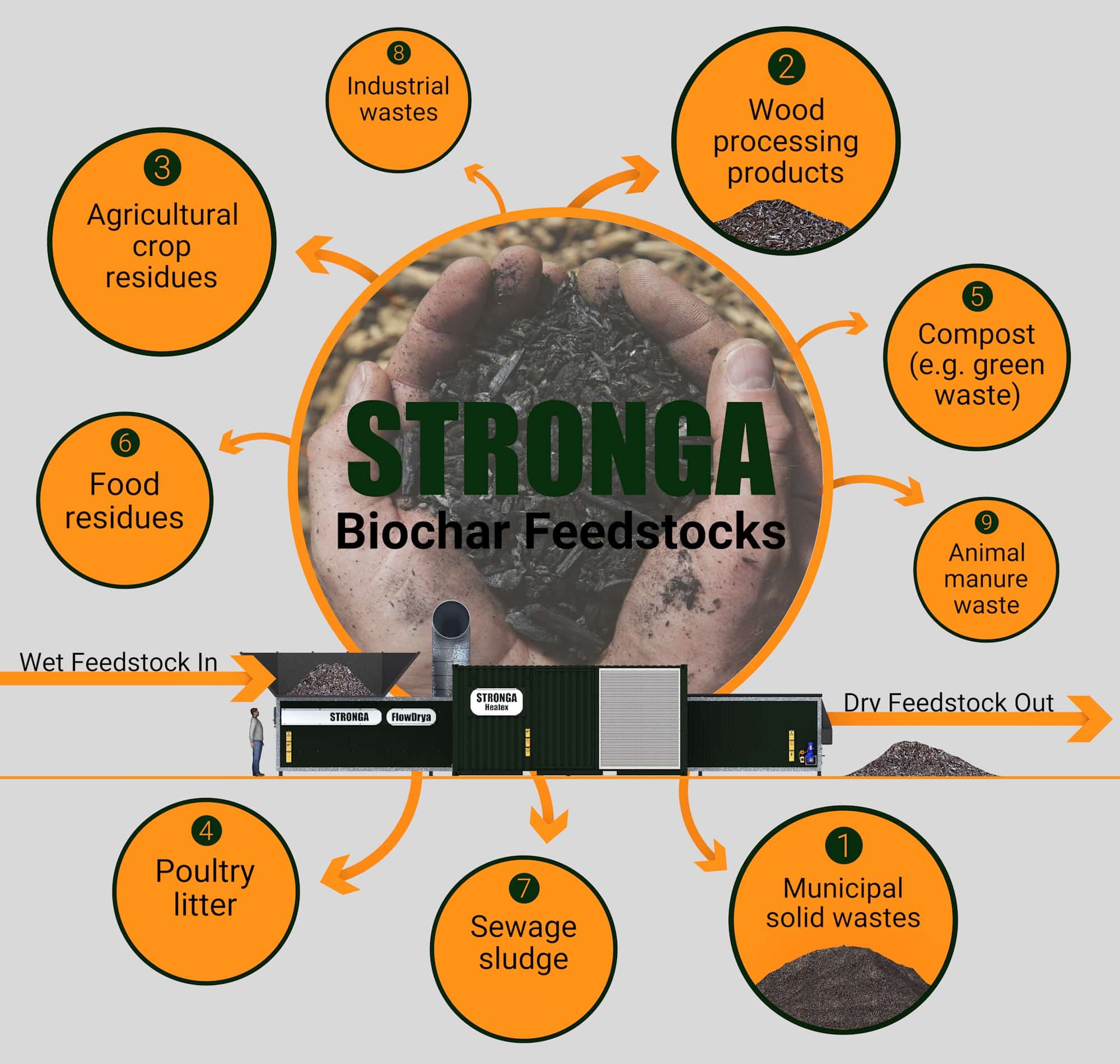

The pyrolysis feedstock type (a few are shown below) has a significant effect on surface area and carbon content of the biochar output. Moisture content and the composition of the feedstock are the other significant influences on biochar value and production efficacy.

The Significant Benefits of Biochar

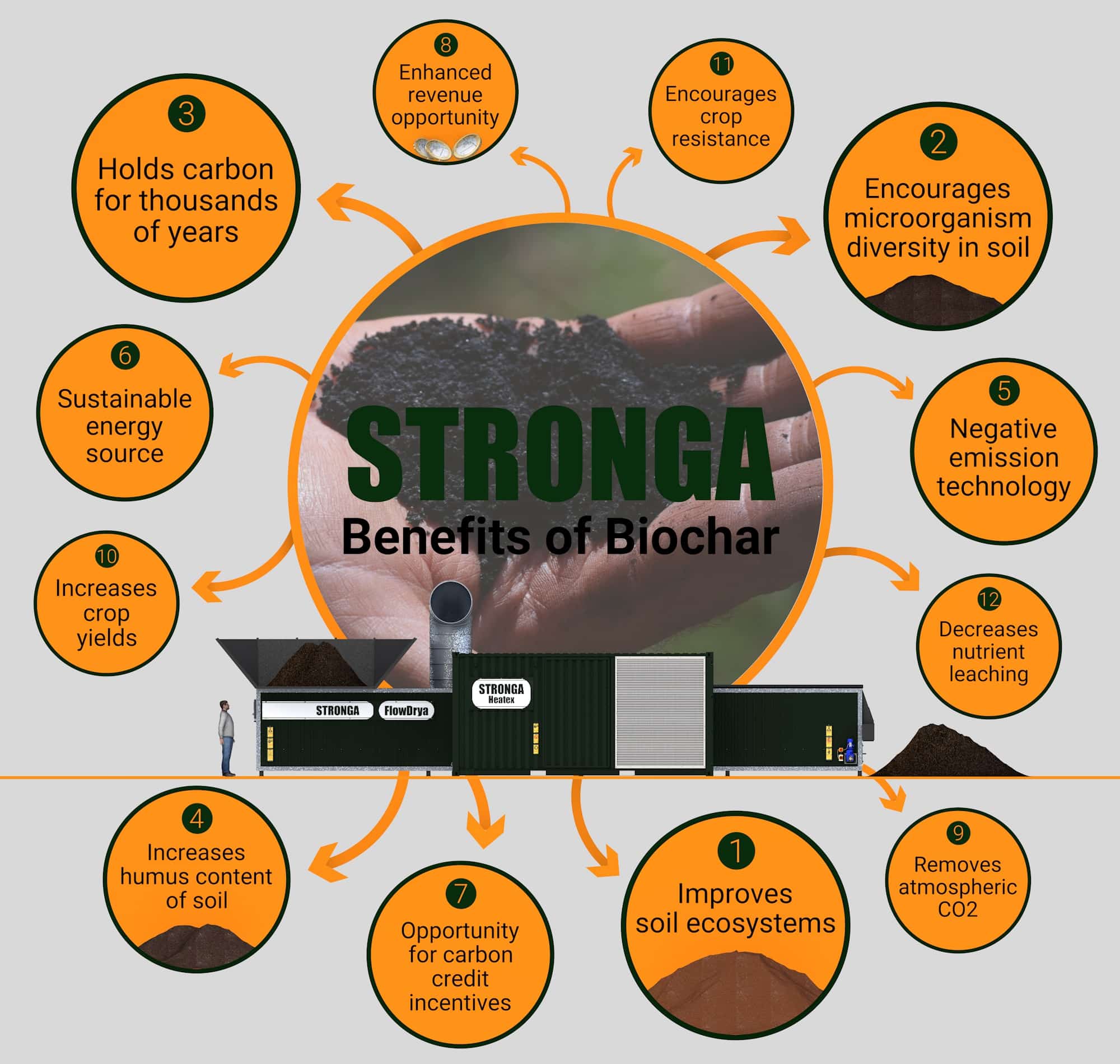

Biochar is quickly becoming recognised on a global-scale for its transformative qualities. The benefits are extensive:

(1) Biochar alters the structure of soil, specifically the organic carbon content, improving the quality, health and yield of crops, through enhanced humic content.

(2) Increasing water-holding capacity, biochar's porous structure allows it to absorb and retain water, making it available to plants in sandy soils or during dry periods. This encourages soil remediation and nutrient absorption by providing suitable habitats for beneficial microorganisms, increasing soil fertility.

(3) Improving soil structure, biochar enhances aggregation and facilitates better water infiltration and storage; ensuring plants have a consistent water supply, reducing surface water evaporation. This contributes to more conservative water-use in the agricultural sector.

(4) Enabling long-term sequestration of carbon, biochar reduces greenhouse gas emissions and helps combat climate change. The conversion of waste to biochar fits with Stronga’s circular-economy vision, respecting resources while reducing GHG emissions.

(5) Biochar has a high cation exchange capacity which allows for enhanced nutrient retention while preventing nutrient leaching; ensuring essential minerals remain available for plants. This reduces the need for chemical fertilisers, promoting sustainable farming practices.

Other benefits of biochar are detailed in the graphic below.

FlowDrya Unlocks Biochar’s Immense Potential

Drying the feedstock prior to pyrolysis has been proven to significantly increase the quality of the biochar output. Excessive moisture can impede thermal-degradation pyrolysis processes, increase energy consumption, and reduce biochar yield; making drying essential in the whole process.

Discover the benefits of using FlowDrya to dry your pyrolysis feedstock:

(1) Drying feedstocks using FlowDrya equipment reduces the energy required to evaporate water during pyrolysis, allowing more energy to be dedicated to the pyrolysis process. This improves the overall energy efficiency of the process and thermal degradation of biomass. Stronga has extensive experience engineering FlowDrya equipment. Speak to our team to discuss your project.

(2) Lower moisture content feedstocks result in biochar with higher carbon content, greater porosity and better structural integrity. These qualities enhance the material’s performance in agricultural applications while reducing waste associated with low-quality biochar produced from high-moisture feedstock.

(3) Drying enhances physicochemical properties of the feedstock, enhancing carbon concentration and energy density of biomass, therefore increasing calorific value. Biochar produced from low moisture feedstock offers better water retention, pollutant absorption and nutrient absorption in soil.

(4) High moisture feedstocks increase the organic volatile compound emissions released during pyrolysis due to increased occurrence of thermal stresses and unburnt compounds. This reduces the structural stability of biochar, combustion quality and surrounding air quality.

To better understand the implications of moisture content in biochar production >

As the demand for biochar grows, producers must be well-equipped to manage moisture content to optimise biochar production. Investing in FlowDrya equipment enables producers to deliver premium biochar while unlocking the immense potential of the resource.

Speak to our friendly team today to benefit from bespoke advice. Together, we can make a significant impact on soil health and climate change – info@stronga.co.uk

Share this post